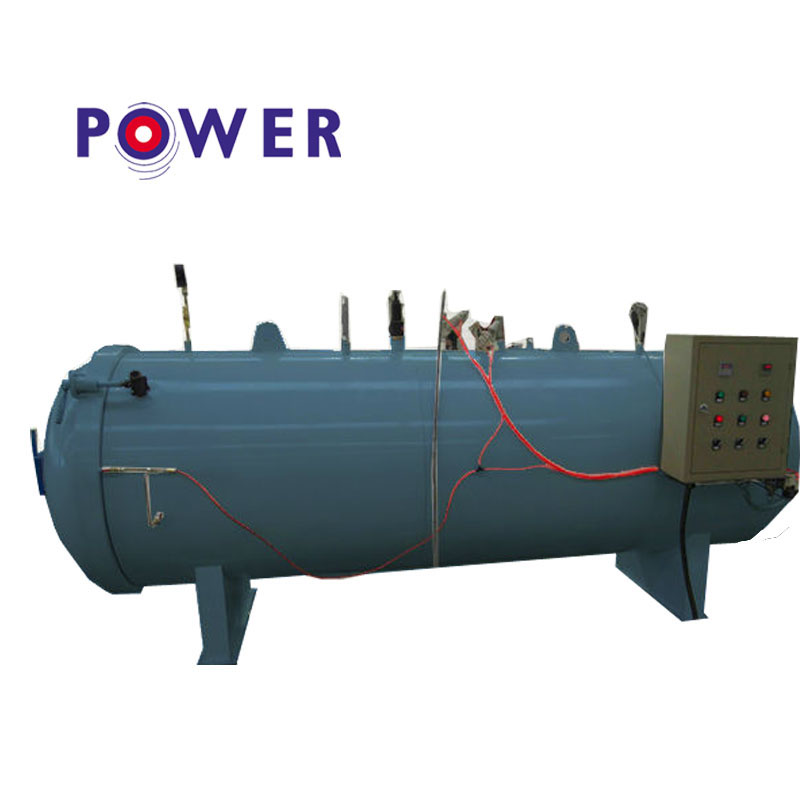

2018 Good Quality Rubber Vulcanizer - Autoclave- Steam Heating Type – Power

2018 Good Quality Rubber Vulcanizer - Autoclave- Steam Heating Type – Power Detail:

Product Description

1. Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.

2. Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve. The air source is depressurized by a set of filter and pressure reducing purification device. Copper pipe is used for pipeline connection.

3. Steam pipeline system: the steam pipeline system shall refer to the drawings design and configuration provided by the manufacturer. The pipeline layout is reasonable, beautiful and convenient for operation and maintenance. Reliable pipeline connection.

4. Vacuum system of vulcanizing tank: used to control the vacuum absorption.

5. Control system: semi-automatic or full-automatic control system, including temperature control, pressure control, etc.

| Model |

φ1500mm×5000mm |

φ1500mm×8000mm |

| Diameter |

φ1500mm |

φ1500mm |

| Straight length |

5000mm |

8000mm |

| Heating mode |

direct steam heating |

direct steam heating |

| Design pressure |

0.8Mpa |

1.58Mpa |

| Design temperature |

175 °C |

203 °C |

| Steel plate thickness |

8mm |

14mm |

| Temperature measurement and control point |

2 points |

2 points |

| Ambient temperature |

Min.-10 ℃ - Max. +40℃ |

Min.-10 ℃ - Max. +40℃ |

| Power |

380, three-phase five-wire system |

380V, three-phase four-wire system |

| Frequency |

50Hz |

50Hz |

Application

Vulcanization of rubber products.

Services

1. Installation service.

2. Maintenance service.

3. Technical support online service provided.

4. Technical files service provided.

5. On-site training service provided.

6. Spare parts replacement and repair service provided.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for 2018 Good Quality Rubber Vulcanizer - Autoclave- Steam Heating Type – Power , The product will supply to all over the world, such as: Kuala Lumpur, Barbados, Riyadh, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.