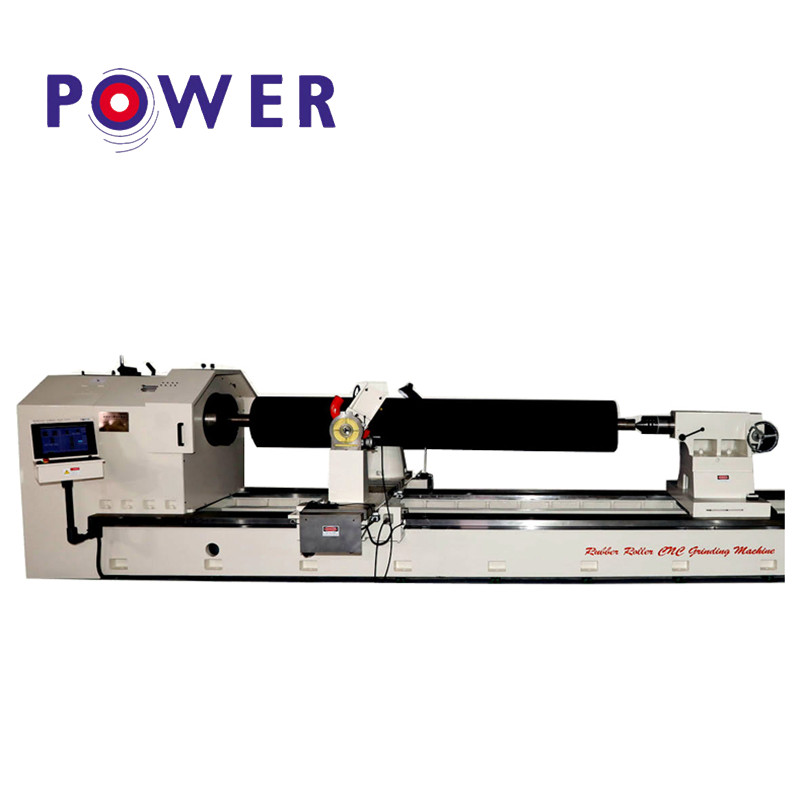

China Supplier CNC Surface Grinding Machine - Rubber Roller Polishing Machine – Power

China Supplier CNC Surface Grinding Machine - Rubber Roller Polishing Machine – Power Detail:

Product Description

1. This equipment is designed as a follow up machine of our PSM series for the rubber roller surface refining process.

2. Meeting critical requirements on the surface smoothness by choosing the abrasive belts with different granularity.

3. The geometric size of rubber roller will remain unchanged.

4. The operating system is simple and easy-to-use.

| Model Number |

PPM-2020 |

PPM-3030 |

PPM-4030 |

| Max Diameter |

7.8″/200mm |

12″/300MM |

16″/400MM |

| Max Length |

78″/2000mm |

118”/3000MM |

118”/3000MM |

| Work Piece Weight |

100 KGS |

200 KGS |

300 KGS |

| Hardness Range |

15-100SH-A |

15-100SH-A |

15-100SH-A |

| Voltage (V) |

220/380/440 |

220/380/440 |

220/380/440 |

| Power (KW) |

2 |

2 |

3 |

| Dimension |

3.2m*1.4m*1.5m |

4.2m*1.6m*1.5m |

4.2m*1.6m*1.5m |

| Type |

Angle Polisher |

Angle Polisher |

Angle Polisher |

| Max Speed (RPM) |

940 |

940 |

940 |

| Sanding Belt Grit |

Customized |

Customized |

Customized |

| Brand Name |

POWER |

POWER |

POWER |

| Certification |

CE,ISO |

CE,ISO |

CE,ISO |

| Warranty |

1 year |

1 year |

1 year |

| Color |

Customized |

Customized |

Customized |

| Condition |

New |

New |

New |

| Place of Origin |

Jinan, China |

Jinan, China |

Jinan, China |

| Need of operator |

1 person |

1 person |

1 person |

| Model Number |

PPM-6040 |

PPM-8060 |

PPM-1280 |

| Max Diameter |

24″/600MM |

32″/800MM |

48″/1200MM |

| Max Length |

158”/4000MM |

240”/6000MM |

315”/8000MM |

| Work Piece Weight |

1500 KGS (with steady rest) |

2000 KGS (with steady rest) |

5000 KGS (with steady rest) |

| Hardness Range |

15-100SH-A |

15-100SH-A |

15-100SH-A |

| Voltage (V) |

220/380/440 |

220/380/440 |

220/380/440 |

| Power (KW) |

6.5 |

8.5 |

12 |

| Dimension |

6.4m*1.7m*1.6m |

8.4m*1.9m*1.8m |

10.5m*2.1m*1.8m |

| Type |

Angle Polisher |

Angle Polisher |

Angle Polisher |

| Max Speed (RPM) |

400 |

300 |

200 |

| Sanding Belt Grit |

Customized |

Customized |

Customized |

| Brand Name |

POWER |

POWER |

POWER |

| Certification |

CE,ISO |

CE,ISO |

CE,ISO |

| Warranty |

1 year |

1 year |

1 year |

| Color |

Customized |

Customized |

Customized |

| Condition |

New |

New |

New |

| Place of Origin |

Jinan, China |

Jinan, China |

Jinan, China |

| Need of operator |

1 person |

1 person |

1 person |

Application

The PPM Series Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.

Services

1. Installation service.

2. Maintenance service.

3. Technical support online service provided.

4. Technical files service provided.

5. On-site training service provided.

6. Spare parts replacement and repair service provided.

Product detail pictures:

Related Product Guide:

We have state-of-the-art tools. Our products are exported towards the USA, the UK and so on, enjoying a fantastic reputation amongst customers for China Supplier CNC Surface Grinding Machine - Rubber Roller Polishing Machine – Power , The product will supply to all over the world, such as: Japan, Manchester, Canberra, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we have got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.