China wholesale Rubber Roller Vulcanization Tank - Rubber Roller – Power

China wholesale Rubber Roller Vulcanization Tank - Rubber Roller – Power Detail:

Product Description

1. Material: Adopts specially formulated rubber compounds imported from the U.S. and Germany to manufacture all kinds of rubber rollers. Natural Rubber, Nitrile rubber, Neoprene, Butyl, EPDM, Polyurethane, Silicone, Fluorine and etc.

2. Production: Being extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality. Our products have sophisticated production technologies and excellent product quality, being recognized by domestic and foreign users. The company has become the designated unit for rubber roller procurement of many large printing factories.

3. Quality Control: Precisely checked with our own made PSF series rubber roller laser measuring instrument.

4. Packing: We regard packaging as a crucial link. Careful and appropriate packaging is fairly important to ensure the good condition and successful delivery of the rubber rolls.

5. Choosing Us: Cherishing professionalism and whole-hearted sincerity, Jinan Power Rubber Roller Equipment Co., Ltd. is dedicated to producing high-quality rubber rollers close to the needs of the era of science and technology. No matter what type of rubber roller you choose, you can definitely find the confidence. We are extremely rigorous with the rubber roller production process, and ensure the highest quality and reliable durability by sparing no efforts to enhance work procedures and integrating technical strengths in all aspects.

6. Different Characteristics of Rubber Roller

- Natural Rubber Roller - excellent flexibility and mechanical strength, good alkali resistance for textiles, leather paper, packaging equipment, such as roller-type compactor and metallurgy, mining and other industries traction roller type.

- Nitrile rubber roller - a good oil resistance, and wear-resistant, anti-aging, heat resistance is also good for printing, printing and dyeing, chemical fiber, paper, packaging, plastics processing equipment and other contact with hydrocarbon oil and fat occasions solvent..

- Neoprene Roller - excellent abrasion resistance, high fire resistance, aging resistance, good heat resistance, oil resistance and acid and corrosion machines for PCB, plastic, leather, printing, food Indian iron, ordinary coating machines.

- Butyl rubber roller - high resistance to chemical solvents, good heat resistance (170℃), good acid, and applied to color printing machinery, tanning machinery, coating equipment.

- EPDM rubber roller - excellent resistance to ozone aging and weather resistance, wide operating temperature can be from -65℃ to 140℃ in long-term work, insulation performance, for plastic printing machinery, tanning machinery, general areas

- Polyurethane rubber roller - a very high mechanical strength and wear resistance, anti-aging and oil resistance is also very good, commonly used in papermaking, chemical fiber, wood processing, plastic processing machinery.

- Silicone rubber roller - to use its high temperature resistance, ozone, chemical inert and non-adhesive plastic for thermal processing of viscous products, such as rolling of polyethylene, embossed, printing and dyeing and the film and fabric coating adhesive , plastic composite, corona processing machinery, is also used for sugar production and release of the packaging machine feed rollers and non-woven manufacturing.

- Fluorine rubber roller - an ultra-high heat, oil, acid, such as performance, gas permeability resistance, electrical insulation, anti-aging, flame-resistant, wear-resistant properties is also very good for special coating equipment.

Application

- Roller for wide digital printing machine.

- Roller for paper milled machinery.

- Roller for textile machinery.

- Roller for plastic film machinery.

- Roller for plywood conveyor system.

- Roller for mine and filter industry.

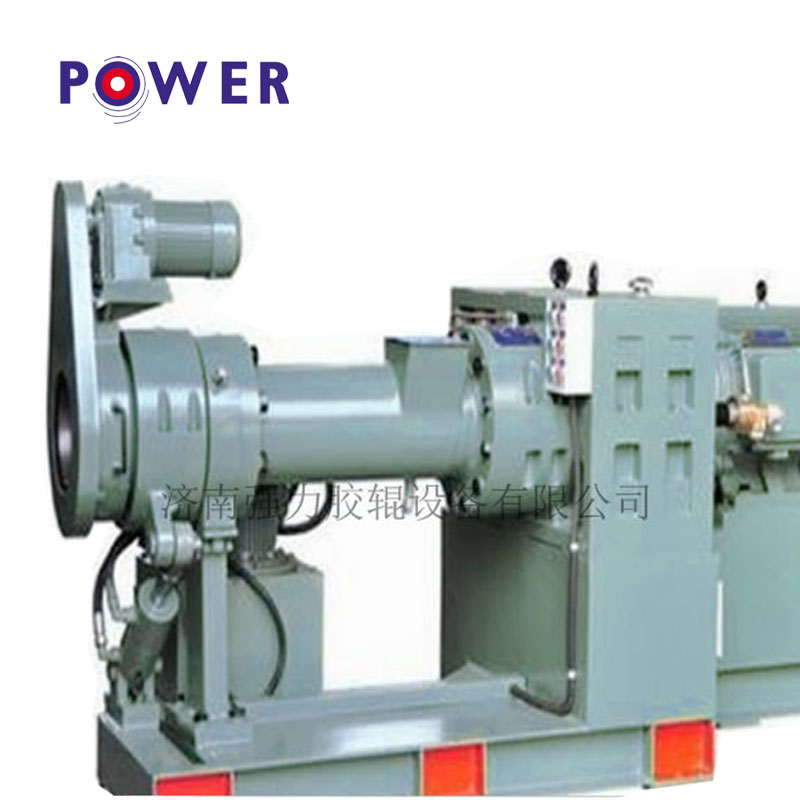

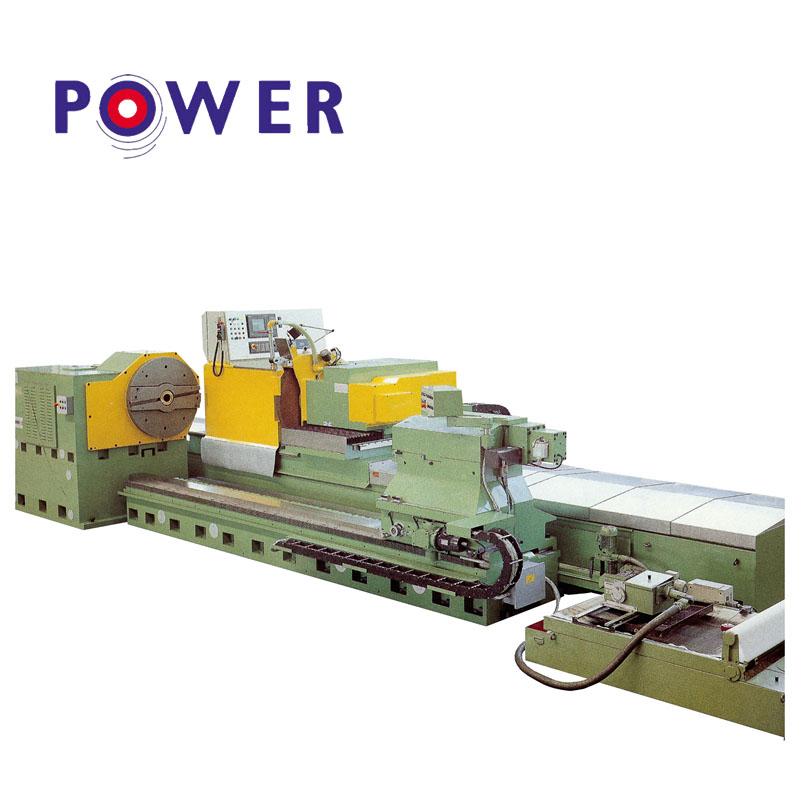

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for China wholesale Rubber Roller Vulcanization Tank - Rubber Roller – Power , The product will supply to all over the world, such as: Portugal, Argentina, Germany, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.