factory Outlets for Straining Extruder - Dispersion Kneader Mixer – Power

factory Outlets for Straining Extruder - Dispersion Kneader Mixer – Power Detail:

Product Feature

1. Long service life

2. Low noise & good sealing performance

3. Large starting torque

4. Wear-resistant

Product Description

1. Self-developed temperature sensor for mixer chamber and fit ±5℃ temperature range.

2. We adopt standard configuration by water cooling and steam heating. Options by different material & process: hot-oil heating, electric heating and/or sectional electric heating & water jacket.

3. Electric control panel system can be customized with PLC control, touch screen, chart recorder and AC or DC driving motor.

4. Standard two-wing mode mixing chamber rotor can be customized to be three-wing mode or intermesh mode.

| Model Number | 1L | 3L | 5L |

| Mixing Capacity | 1L | 3L | 5L |

| Produce Weight(Once) | About 0.75-2KG/unit | About 1.5-5KG/unit | About 04-8KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 3.75 | 7.5 | 11 |

| Tilting Motor (KW) | 0.4 | 0.4 | 0.4 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 38/28 | 38/28 | 38/28 |

| Weight (KG) | 900 | 1000 | 1100 |

| Feeding Mode | Front | Front | Front |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 2100*1000*2100 | 2100*1000*2100 | 2300*1100*2000 |

| Model Number | 10L | 20L | 35L |

| Mixing Capacity | 10L | 20L | 35L |

| Produce Weight(Once) | About 8-15KG/unit | About 15-25KG/unit | About 26-45KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 15 | 30 | 55 |

| Tilting Motor (KW) | 0.75 | 1.5 | 1.5 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 37/31 | 35/29 | 35/27 |

| Weight (KG) | 2300 | 4000 | 6500 |

| Feeding Mode | Front | Front | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 2200*1350*2250 | 2500*1480*2600 | 3000*1920*2840 |

| Model Number | 55L | 75L | 110L |

| Mixing Capacity | 55L | 75L | 110L |

| Produce Weight(Once) | About 45-75KG/unit | About 60-85KG/unit | About 100-140KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 75 | 110 | 160 |

| Hydraulic Cylinder Hopper/Tilting Motor (KW) | 2.2 | 5.5 | 5.5 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 36/27 | 36/27 | 37/30 |

| Weight (KG) | 8500 | 10500 | 14000 |

| Feeding Mode | Front/Back | Front/Back | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 3250*2300*3450 | 3800*2400*3650 | 4150*2950*3850 |

| Model Number | 150L | 250L | 55L (Intermesh) |

| Mixing Capacity | 150L | 250L | 55L |

| Driving Motor (KW) | 220 | 350 | 185 |

| Hydraulic Cylinder Hopper/Tilting Motor (KW) | 7.5 | 11 | 3.75 |

| Tilting Angle | 125° | 140° | 140° |

| Agitator Shaft Speed (rpm) | 38/30 | 37/30 | 40/40 |

| Weight (KG) | 21000 | 43000 | 16000 |

| Feeding Mode | Front/Back | Front/Back | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Temperature Control System | Automatic water cooling | Automatic water cooling | |

| Dimensions (LXWXH) | 4300*3000*4700 | 4950*3700*5000 | 3800*2400*3650 |

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

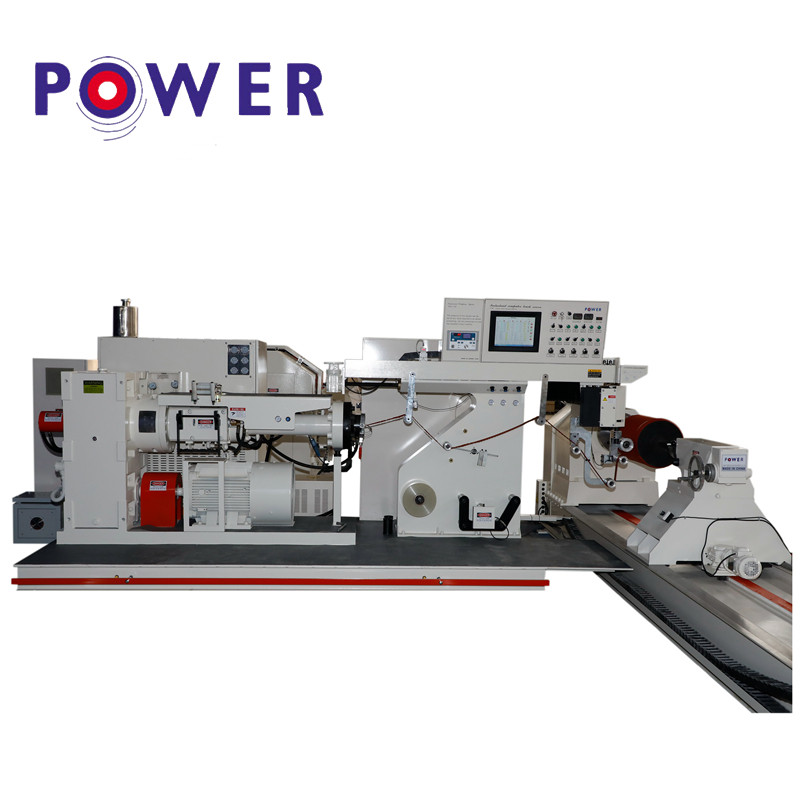

Product detail pictures:

Related Product Guide:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for factory Outlets for Straining Extruder - Dispersion Kneader Mixer – Power , The product will supply to all over the world, such as: New Zealand, Maldives, Ukraine, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.