High Quality Dust Collector System - Balance Machine – Power

High Quality Dust Collector System - Balance Machine – Power Detail:

Feature

1. Fast running speed

2. High reliability & precision

3. Stable performance

Product Description

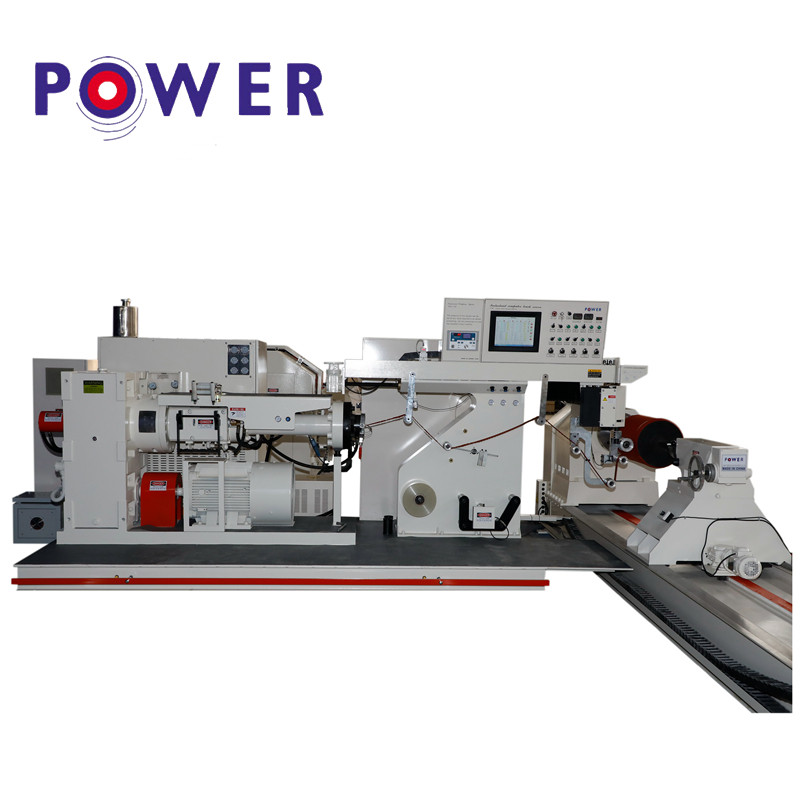

Mainly used for balance verification of large and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and other rotating workpieces.

The machine adopts ring belt drive or gear box universal joint transmission, and frequency conversion motor drive to ensure the balanced quality and precision of the workpiece.

The machine has the characteristics of wide speed range, large driving power and high working efficiency.

| Model Number | GP-B3000H | GP-U3000H | GP-U10000H |

| Transmission | Belt Drive | Universal Joint | Universal Joint |

| Workpiece weight range (kg) | 3000 | 3000 | 10000 |

| Workpiece Max. Outer Diameter (mm) | Ø2100 | Ø2100 | Ø2400 |

| Distance between two supports (mm) | 160-3780 | Minimum 60 | Min. 320 |

| Support shaft diameter range (mm) | Standard Ø25 ~ 180 | Standard Ø25 ~ 240 | Ø60~400 |

| The maximum diameter of the belt drive (mm) | Ø900 | N/A | N/A |

| Rotational speed when the diameter of the workpiece transmission is 100mm (r / min) | 921, 1329 + stepless speed regulation | N/A | N/A |

| The maximum distance from the end of the universal joint to the center of the right support (mm) | N/A | 3900 | 6000 |

| Spindle speed (r/min) | N/A | 133,225,396.634,970 + stepless speed regulation | Stepless speed regulation |

| Motor Power (KW) | 7.5 (AC frequency conversion) | 7.5 (AC frequency conversion) | 22(AC frequency conversion) |

| Universal coupling torque (N·m) | N/A | 700 | 2250 |

| Lathe length (mm) | 4000 | 5000 | 7500 |

| Minimum reachable residual imbalance / per side (e mar) | ≤0.5g·mm/kg | ≤1gmm / kg | ≤0.5g·mm/kg |

| Color | Customized | Customized | Customized |

| Condition | New | New | New |

Services

1. Installation service.

2. Maintenance service.

3. Technical support online service provided.

4. Technical files service provided.

5. On-site training service provided.

6. Spare parts replacement and repair service provided.

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for High Quality Dust Collector System - Balance Machine – Power , The product will supply to all over the world, such as: Peru, Las Vegas, Lesotho, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.