High reputation Rubber Internal Mixing Machine - Dispersion Kneader Mixer – Power

High reputation Rubber Internal Mixing Machine - Dispersion Kneader Mixer – Power Detail:

Product Feature

1. Long service life

2. Low noise & good sealing performance

3. Large starting torque

4. Wear-resistant

Product Description

1. Self-developed temperature sensor for mixer chamber and fit ±5℃ temperature range.

2. We adopt standard configuration by water cooling and steam heating. Options by different material & process: hot-oil heating, electric heating and/or sectional electric heating & water jacket.

3. Electric control panel system can be customized with PLC control, touch screen, chart recorder and AC or DC driving motor.

4. Standard two-wing mode mixing chamber rotor can be customized to be three-wing mode or intermesh mode.

| Model Number | 1L | 3L | 5L |

| Mixing Capacity | 1L | 3L | 5L |

| Produce Weight(Once) | About 0.75-2KG/unit | About 1.5-5KG/unit | About 04-8KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 3.75 | 7.5 | 11 |

| Tilting Motor (KW) | 0.4 | 0.4 | 0.4 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 38/28 | 38/28 | 38/28 |

| Weight (KG) | 900 | 1000 | 1100 |

| Feeding Mode | Front | Front | Front |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 2100*1000*2100 | 2100*1000*2100 | 2300*1100*2000 |

| Model Number | 10L | 20L | 35L |

| Mixing Capacity | 10L | 20L | 35L |

| Produce Weight(Once) | About 8-15KG/unit | About 15-25KG/unit | About 26-45KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 15 | 30 | 55 |

| Tilting Motor (KW) | 0.75 | 1.5 | 1.5 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 37/31 | 35/29 | 35/27 |

| Weight (KG) | 2300 | 4000 | 6500 |

| Feeding Mode | Front | Front | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 2200*1350*2250 | 2500*1480*2600 | 3000*1920*2840 |

| Model Number | 55L | 75L | 110L |

| Mixing Capacity | 55L | 75L | 110L |

| Produce Weight(Once) | About 45-75KG/unit | About 60-85KG/unit | About 100-140KG/unit |

| Batch Time | About 4-7 times/hour | About 4-7 times/hour | About 4-7 times/hour |

| Compressed Air Pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Driving Motor (KW) | 75 | 110 | 160 |

| Hydraulic Cylinder Hopper/Tilting Motor (KW) | 2.2 | 5.5 | 5.5 |

| Tilting Angle | 125° | 125° | 125° |

| Agitator Shaft Speed (rpm) | 36/27 | 36/27 | 37/30 |

| Weight (KG) | 8500 | 10500 | 14000 |

| Feeding Mode | Front/Back | Front/Back | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Dimensions (LXWXH) | 3250*2300*3450 | 3800*2400*3650 | 4150*2950*3850 |

| Model Number | 150L | 250L | 55L (Intermesh) |

| Mixing Capacity | 150L | 250L | 55L |

| Driving Motor (KW) | 220 | 350 | 185 |

| Hydraulic Cylinder Hopper/Tilting Motor (KW) | 7.5 | 11 | 3.75 |

| Tilting Angle | 125° | 140° | 140° |

| Agitator Shaft Speed (rpm) | 38/30 | 37/30 | 40/40 |

| Weight (KG) | 21000 | 43000 | 16000 |

| Feeding Mode | Front/Back | Front/Back | Front/Back |

| Temperature Control Range | ±5℃ | ±5℃ | ±5℃ |

| Temperature Control System | Automatic water cooling | Automatic water cooling | |

| Dimensions (LXWXH) | 4300*3000*4700 | 4950*3700*5000 | 3800*2400*3650 |

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

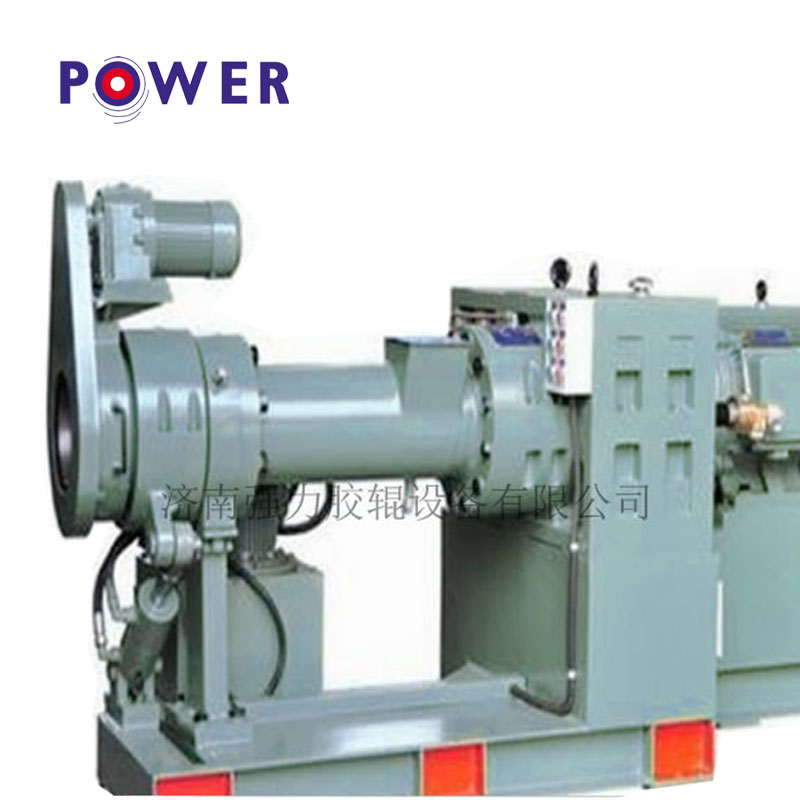

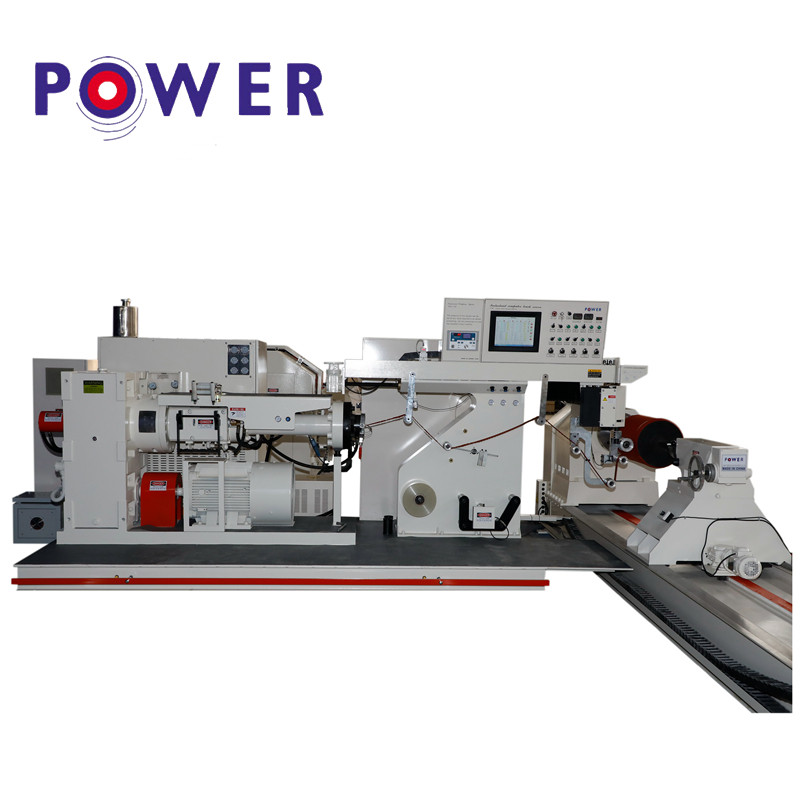

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for High reputation Rubber Internal Mixing Machine - Dispersion Kneader Mixer – Power , The product will supply to all over the world, such as: Gambia, Mumbai, Iraq, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.