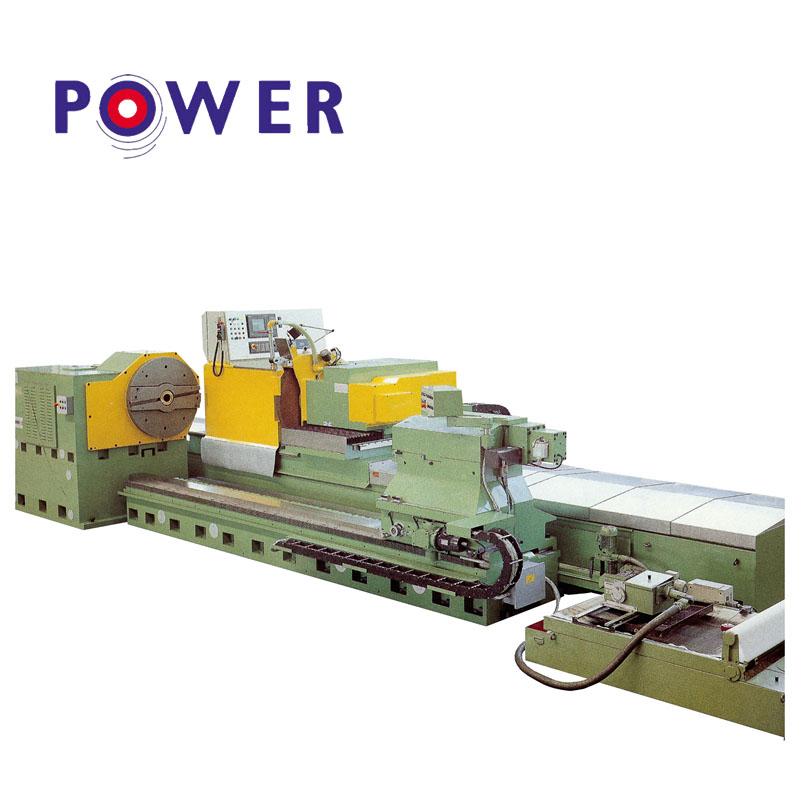

High reputation Rubber Internal Mixing Machine - Open Type Rubber Mixing Mill – Power

High reputation Rubber Internal Mixing Machine - Open Type Rubber Mixing Mill – Power Detail:

Product Feature

1. Made of high quality material

2. Easy installation directly on plain ground

3. Enforce cycle cooling system

4. Safe and efficient

Product Description

1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.

2. Machine can be placed on the plain ground directly, other installation method is unnecessary.

3. The roller bearing supports the heavy loading and high temperature. Using roll bearing double the size and use less lubrication oil, able to use longer and easy to maintain.

4. All the parts of the machine are processed by rust proofing with chromium, to prevent the key parts polluted.

5. Enforce cycle cooling system, enhance the cooling effect by using spin joint and enlarge pipe.

6. Using energizing mechanic power off system, guarantee the well and speedy function under the long term using.

|

Model |

φ9″ |

φ12″ |

φ14″ |

φ16″ |

|

Roll Size (D/L) |

230*635 |

300*700 |

360*920 |

400*1060 |

|

Linear Speed (M/Min) |

11.8 |

15.1 |

19 |

20.65 |

|

Front Roll RPM |

16.3 |

16.1 |

16.5 |

16.44 |

|

Roll Ratio (Front/Back) |

1:1.27* |

1:1.27* |

1:1.27* |

1:1.27* |

|

Produce Weight(Once) |

8-12 KG |

14-20 KG |

20-25 KG |

25-35 KG |

|

Motor Power |

15KW* |

22KW* |

37KW/30KW* |

55KW/45KW* |

|

Weight (KG) |

2800 |

4300 |

5800 |

8000 |

|

Dimensions (LXWXH) |

2528*1053*1235 |

2754*1275*1657 |

3700*1425*1870 |

4000*1500*1870 |

|

Bush |

Bearing Type |

Bearing Type |

Bearing Type |

Bearing Type |

|

Receiver Material |

Stainless Steel |

Stainless Steel |

Stainless Steel |

Stainless Steel |

|

Cooling Mode |

Pressurized Cooling Rotating Joint |

|||

|

Emergency Stop |

Press Button Brake & Foot Brake |

|||

|

Transmission |

Low Noise Gear Box Gear |

|||

|

* Ratio & Motor Power can be customized by different material requirements. |

||||

|

Model |

φ18″ |

φ22″ |

φ24″ |

φ26″ |

|

Roll Size (D/L) |

450*1200 |

55*1530 |

610*1830 |

660*2130 |

|

Linear Speed (M/Min) |

23.22 |

28.29 |

31.6 |

34.2 |

|

Front Roll RPM |

16.43 |

16.38 |

16.5 |

16.5 |

|

Roll Ratio (Front/Back) |

1:1.27* |

1:1.29* |

1:1.29* |

1:1.29* |

|

Produce Weight(Once) |

30-50 KG |

50-60 KG |

120-130 KG |

160-170 KG |

|

Motor Power |

75KW/55KW* |

110KW/90KW* |

160KW/132KW* |

220KW/160KW* |

|

Weight (KG) |

12800 |

18500 |

25500 |

32000 |

|

Dimensions (LXWXH) |

4560*1670*2020 |

5370*1950*2200 |

6100*2050*2200 |

6240*3350*2670 |

|

Bush |

Bearing Type |

Bearing Type |

Bearing Type |

Bearing Type |

|

Receiver Material |

Stainless Steel |

Stainless Steel |

Stainless Steel |

Stainless Steel |

|

Cooling Mode |

Pressurized Cooling Rotating Joint |

|||

|

Emergency Stop |

Press Button Brake & Foot Brake |

|||

|

Transmission |

Low Noise Gear Box Gear |

|||

|

* Ratio & Motor Power can be customized by different material requirements. |

||||

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for High reputation Rubber Internal Mixing Machine - Open Type Rubber Mixing Mill – Power , The product will supply to all over the world, such as: Frankfurt, Manila, moldova, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!