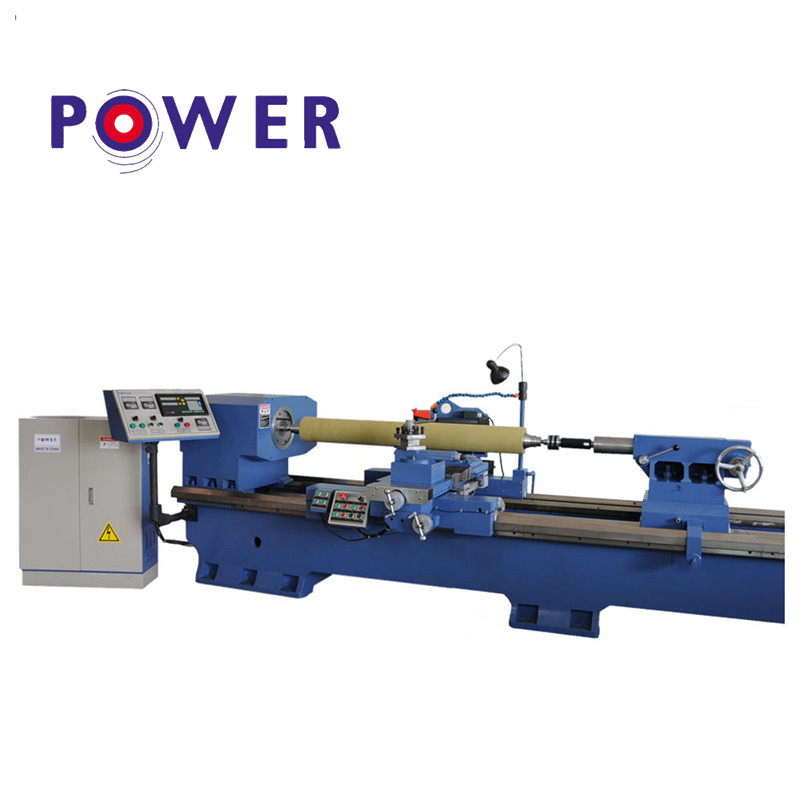

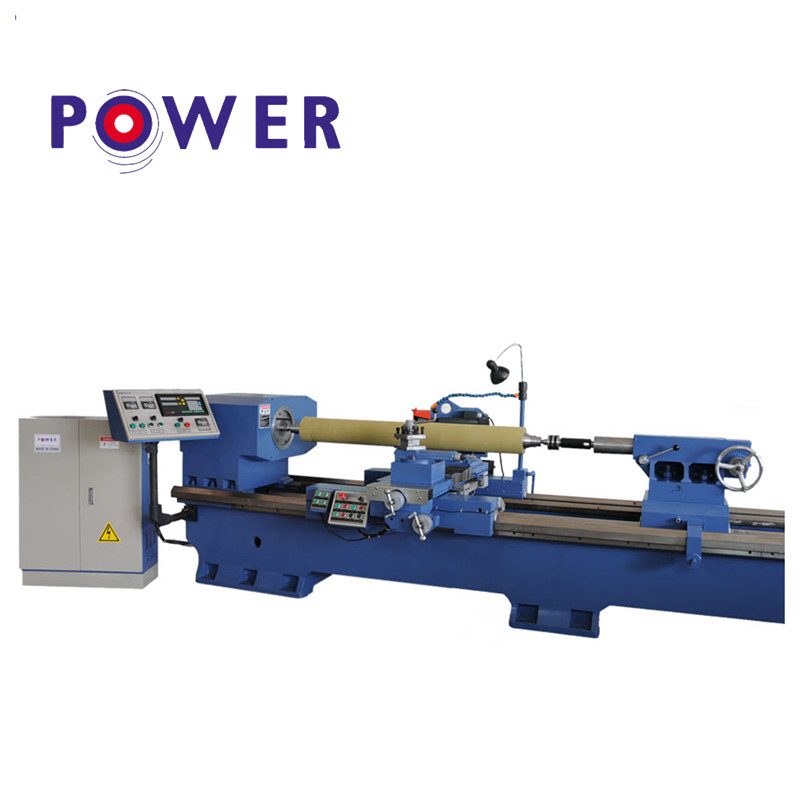

New Delivery for Surface Grinding - Rubber Roller General Grinding Machine – Power

New Delivery for Surface Grinding - Rubber Roller General Grinding Machine – Power Detail:

Product Description

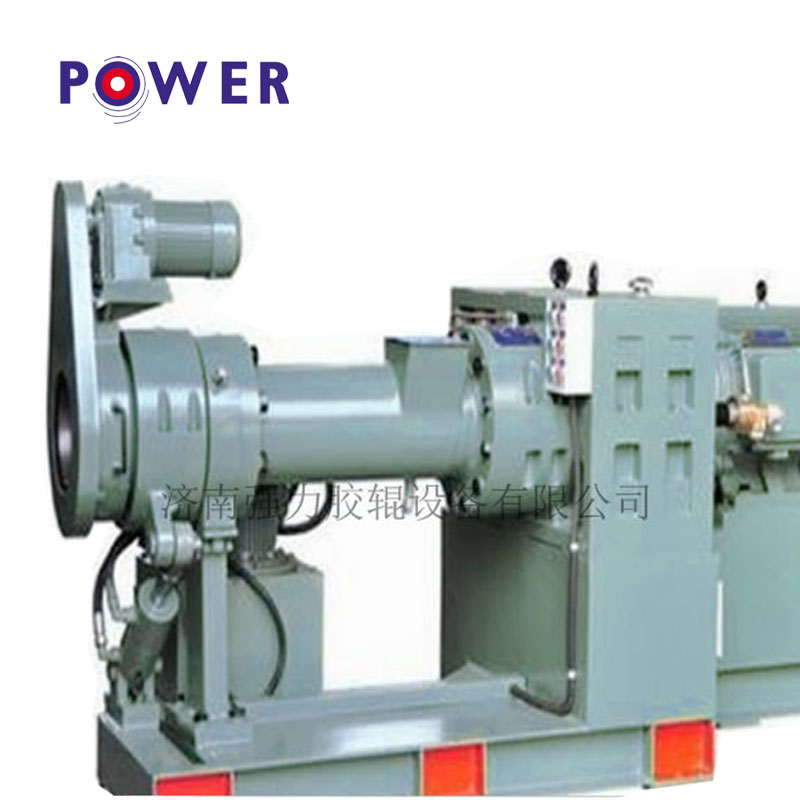

1. Standard equipment of PSM series includes:

a.a full flood re-circulating coolant system

b.motorized tailstock

c.variable speed travels and spindle drives

d.front and rear independently operated carriage tables

e.a direct drive grinding head mounted on the rear

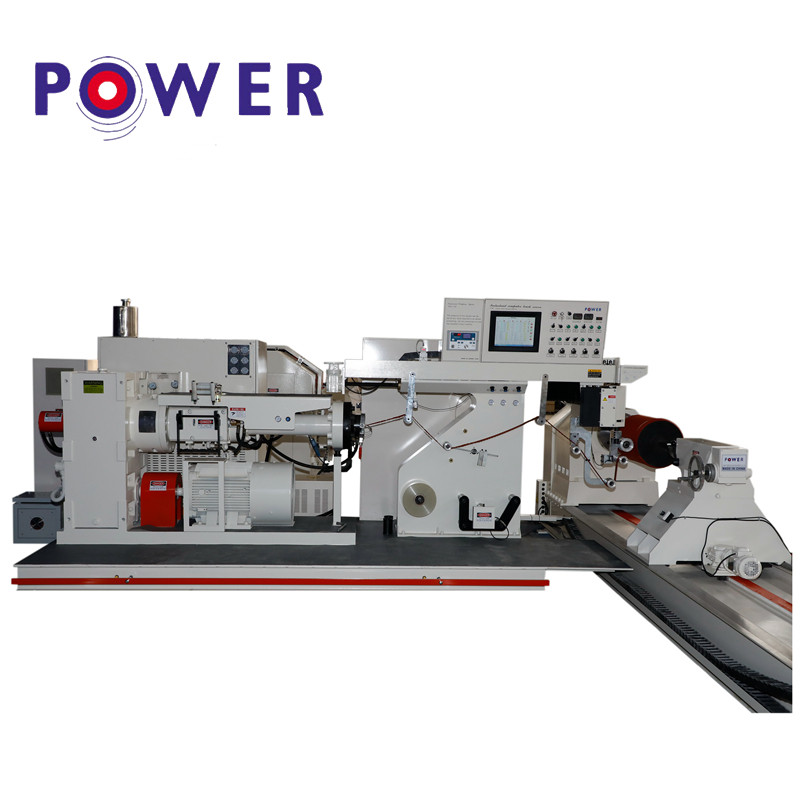

2. Specially designed to replace the traditional roller grinding process method.

3. Two medium carriage tables assembled to ensure accurate performance and operating stability.

4. The max. linear speed of grinding head is over 90m/s. Production efficiency is highly increased and the geometric size is guaranteed.

5. Advanced measuring device which has the function of timely checking the processing data and providing effective help to control the grinding size can be upgrade upon request.

6. Capable of realizing expansion of processing of special-shaped rubber rollers.

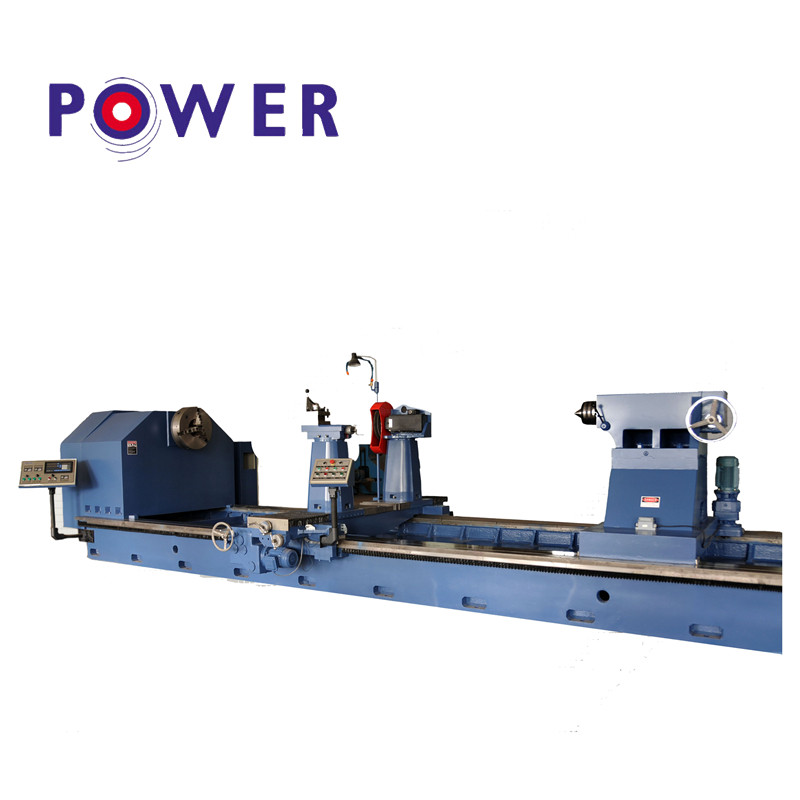

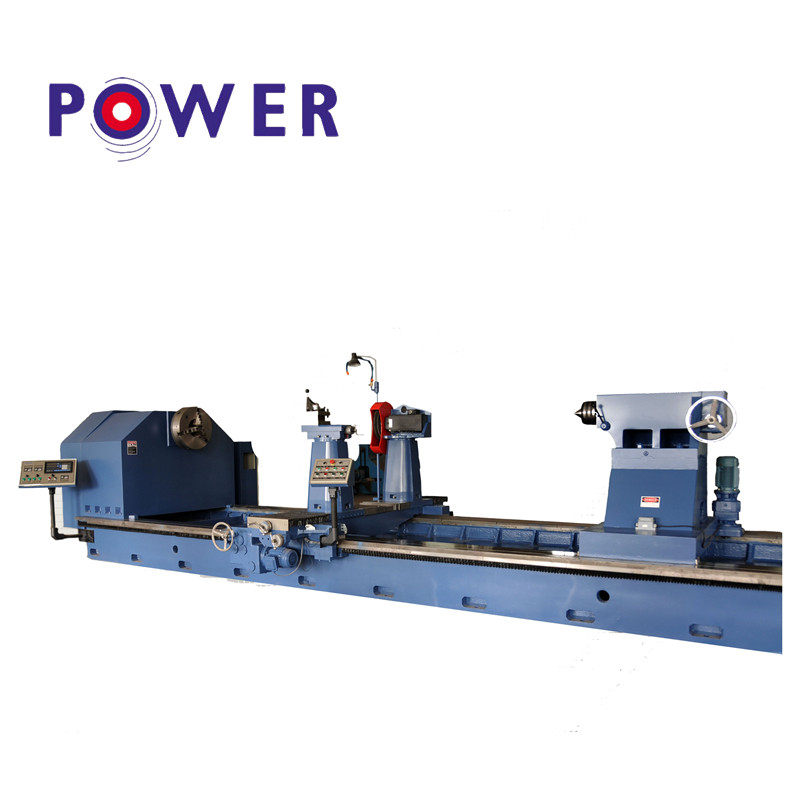

| Model Number | PSM-4020 | PSM-8040 | PSM-1260 | PSM-1680 |

| Max Diameter | 16”/400MM | 32”/800MM | 47′/1200MM | 63′/1600MM |

| Max Length | 80”/2000MM | 158”/4000MM | 236”/6000MM | 315”/8000MM |

| Work Piece Weight | 500kg | 1000kg | 2000kg | 3000kg |

| Hardness Range | 15-120SH-A | 15-120SH-A | 15-120SH-A | 15-120SH-A |

| Voltage (V) | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 |

| Power (KW) | 10 | 15 | 18 | 22 |

| Dimension | 4m*1.4m*1.4m | 6.5m*1.6m*1.6m | 8m*1.8m*1.8m | 11m*2.2m*1.8m |

| Type | Cylindrical | Cylindrical | Cylindrical | Cylindrical |

| CNC or Not | Normal | Normal | Normal | Normal |

| Grinding Wheel | Alloy | Alloy | Alloy | Alloy |

| Function | Grinding & Cutting | Grinding & Cutting | Grinding & Cutting | Grinding & Cutting |

| Brand Name | POWER | POWER | POWER | POWER |

| Certification | CE,ISO | CE,ISO | CE,ISO | CE,ISO |

| Warranty | 1 year | 1 year | 1 year | 1 year |

| Color | Customized | Customized | Customized | Customized |

| Condition | New | New | New | New |

| Place of Origin | Jinan, China | Jinan, China | Jinan, China | Jinan, China |

| Need of operator | 1 person | 1 person | 1 person | 1 person |

Application

PSM series rubber roller grinding machine is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment.

Mounted grinding head on the standard metal processing lathe is one of the traditional methods to manufacture rubber roller, which leads the quality of roller is difficult to reach the higher requirement.

With the consideration of the rubber characteristics, safe production and higher efficiency, we designed the PSM series grinding machine with lower and wider lathe body to reduce vibration, and selected alloy grinding wheels for surface processing.

We also provide the CNC grinding machine with grooving functions for you to select.

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for New Delivery for Surface Grinding - Rubber Roller General Grinding Machine – Power , The product will supply to all over the world, such as: Leicester, Bandung, Netherlands, More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.