News

-

Production of rubber products

1. Basic process flow With the rapid development of modern industry, especially the chemical industry, there are various types of rubber products, but their production processes are basically the same. The production process of produ...Read more -

VULCANIZING MACHINE AUTOCLAVE

The main purpose of the rubber roller vulcanization tank is: Used for vulcanization of rubber rollers, during production, the outer surface of the rubber roller needs to be vulcanized to become a finished product. This vulcanization process requires a high-temperature and high-pressure environme...Read more -

RUBBER REFINING PROCESS OF OPEN TYPE RUBBER MIXING MILL

Why does rubber need to be vulcanized? What are the benefits of vulcanizing rubber? Although rubber raw rubber also has some useful application characteristics, it also has many drawbacks, such as low strength and low elasticity; Cold makes it hard, hot makes it sticky; Easy to age, etc. As earl...Read more -

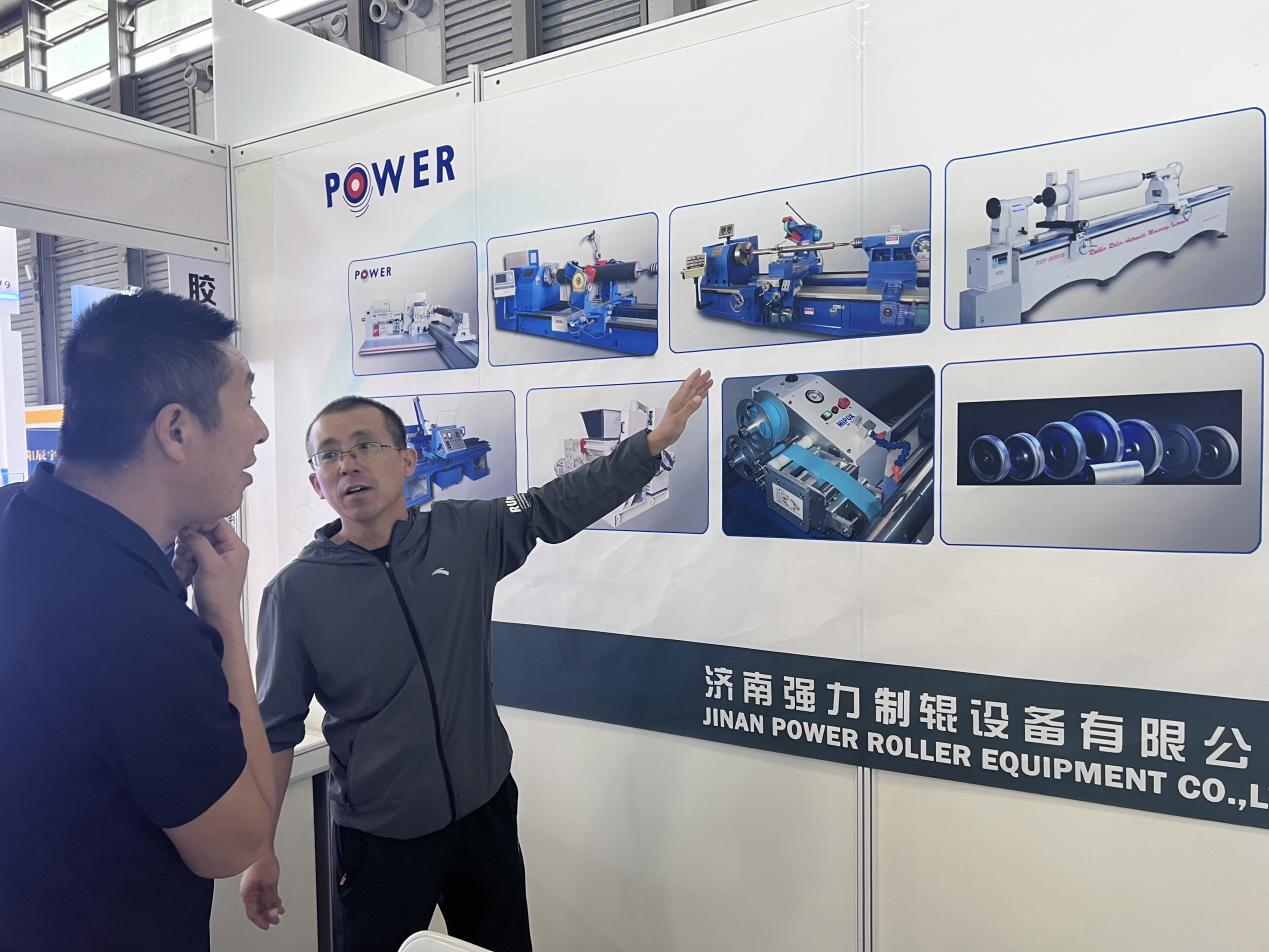

Discover Innovation at RubberTech China 2023!

We’re thrilled to announce that RubberTech China 2023 is now underway, and Jinan Power Roller Equipment Co., a company with over two decades of dedication to the rubber roller processing industry, is leading the way at this exciting event! Who We Are: Established in 1998, Jinan Power Rolle...Read more -

Application industry of rubber rollers II

Printing rubber roller series. 1. Laminated rubber rollers are used as special accessories for printing machinery. 2. Iron printing roller is used for iron printing machinery. 3. Alcohol fountain roller is mainly used on printing machines. 4. The gravure printing roller is mainly used on the pri...Read more -

Application industry of rubber rollers I

The rubber roller used in printing and dyeing machinery for printing, rolling liquid, pad dyeing, and fabric guiding. It is divided into two categories: active roller and passive roller. The active and passive rollers are used together. The hardness of the active roller cover rubber is high, wit...Read more -

Dampening rubber roller Textile Rubber Roll

The dampening rubber roller is a type of rubber roller that is commonly used in printing presses to help regulate the flow of ink onto the paper. These rollers are typically made by wrapping a layer of specialized rubber around a metal core and then treating the surface of the rubber with various...Read more -

POWER is ready to attend annual meeting organized by the Rubber Roller Group in USA

Dear Customers of Jinan Power Roller Equipment, Greetings! In this season of blooming flowers, we are thrilled and proud to announce that Jinan Power Roller Equipment Co., Ltd. is going to attend the annual meeting organized by the Rubber Roller Group in USA, striving to win more respect and mar...Read more -

Overall Solution Supplier for rubber roller manufacture – Visits from customers

Workshop Daily: customers come to visit Jinan Power factory Today’s protagonist:Rubber roller grinding machineRead more -

Classification and characteristics of special rubber

Synthetic rubber is one of the three major synthetic materials and is widely used in various aspects of industry, national defense, transportation and daily life. High-performance and functional synthetic rubber is a key advanced basic material necessary for the development of the new era, and i...Read more -

Compounding silicone rubber molding process

1. Application of compounding silicone rubber technology Kneading silicone rubber is a synthetic rubber that is repeatedly refined by adding raw silicone rubber to a double-roll rubber mixer or a closed kneader and gradually adding silica, silicone oil, etc. and other additives. It can be widely...Read more -

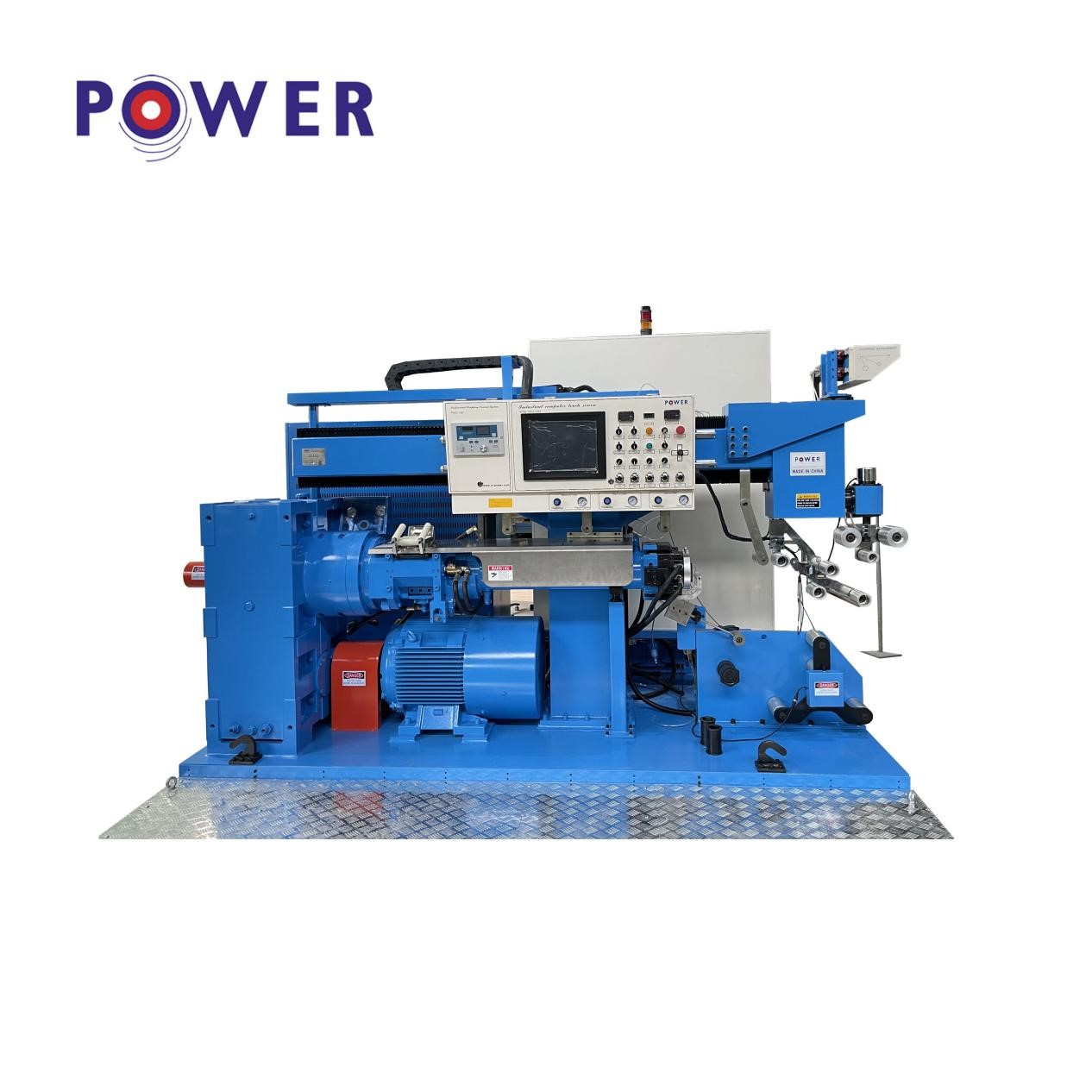

Rubber Roller Covering Machine

The rubber rolerl covering machine is an automatic integrated equipment for wrapping and wrapping rubber on the surface of the rubber roll, which greatly improves the production efficiency of the rubber roll factory in processing and manufacturing rubber roll products. It is a mechanical equipmen...Read more