News

-

Post-vulcanization treatment of rubber products

Rubber products often require some post-processing after vulcanization to become qualified finished products. This includes: A. The edge trimming of rubber mold products makes the surface of the products smooth and the overall dimensions meet the requirements; B. After some special process proces...Read more -

How to repair the damage of rubber extruder screw and barrel

Repair of rubber extruder screw 1. The twisted screw should be considered according to the actual inner diameter of the barrel, and the outer diameter deviation of the new screw should be given according to the normal clearance with the barrel. 2. After the thread surface with the reduced diamet...Read more -

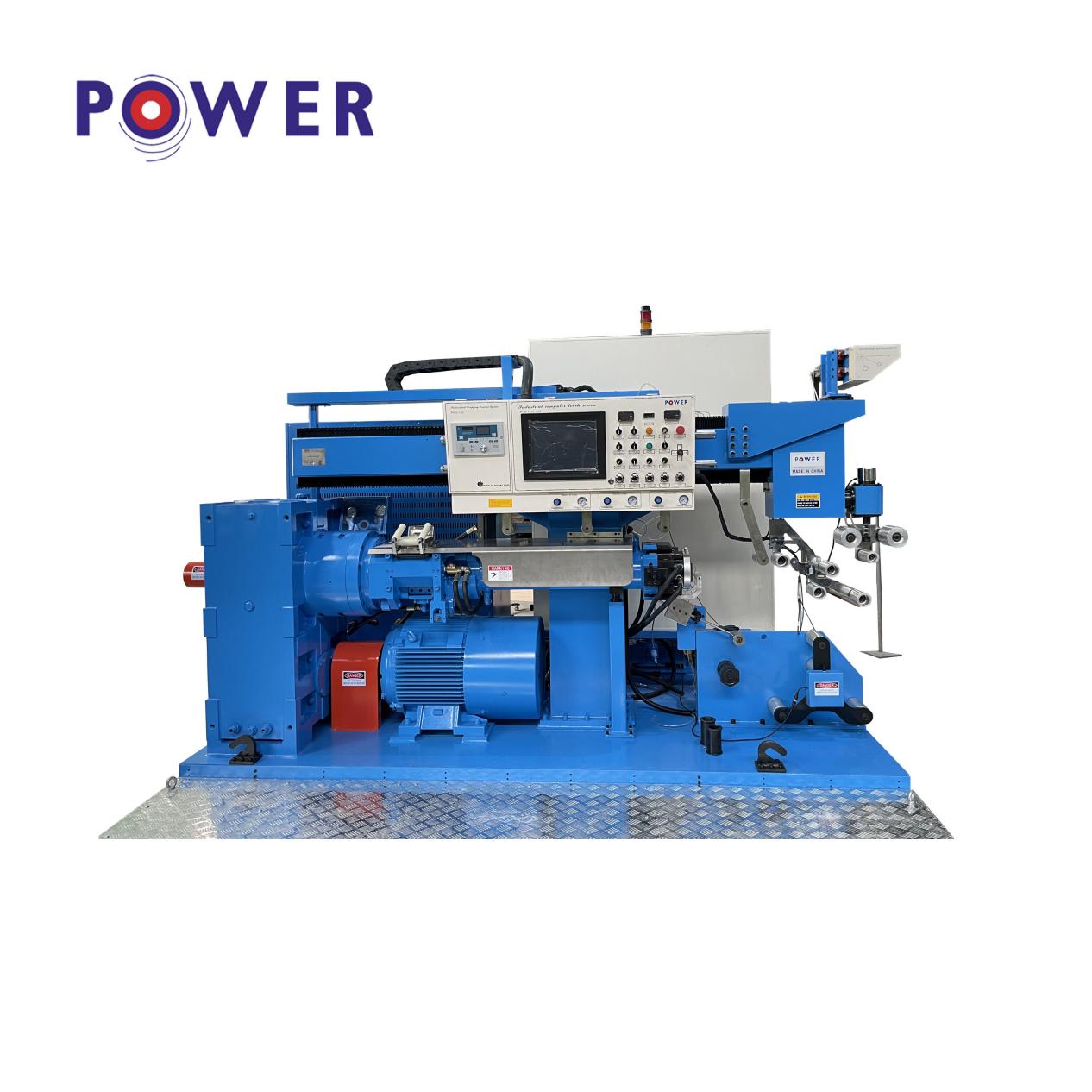

Common problems of rubber roller covering machine

The automatic rubber roll covering machine is designed and produced to improve and improve the lagging process. Suitable models can be selected for different industries, and advanced and mature equipment will bring higher efficiency to your production. Features of rubber roller covering machin...Read more -

Some problems of rubber roller covering machine

The design and production of automatic rubber roller covering machine is to improve and improve the lagging process. You can choose the right model for different industries. Advanced and mature equipment will bring higher efficiency to your production. Features of rubber roller covering machine:...Read more -

Several common rubber identification methods

1. Resistance to medium weight gain test The finished product can be sampled, soaked in one or several selected media, weighed after a certain temperature and time, and the type of material can be inferred according to the weight change rate and the hardness change rate. For example, immersed in ...Read more -

Introduction of rubber extruder and extruder type

Introduction of rubber extruder Rubber extruder is a basic equipment in the rubber industry and one of the key equipments affecting product quality. It plays a very important role in the production process of tires and rubber products. The development of foreign rubber extruders has experienced ...Read more -

The Rubber Vulcameter

1. The function of the rubber vulcanizer The rubber vulcanization tester (referred to as the vulcanizer) is used to analyze and measure the scorch time, positive vulcanization time, vulcanization rate, viscoelastic modulus and vulcanization flat period of the rubber vulcanization process. Resear...Read more -

The operation process and requirements of the close mixer

1. The first start after stopping for a long time should be carried out according to the requirements of the above-mentioned idling test and load test run. For the swing type discharge door, there are two bolts on both sides of the discharge door to prevent the discharge from opening when parke...Read more -

Vulcanizing machine maintenance

As a conveyor belt joint tool, the vulcanizer should be maintained and maintained like other tools during and after use to prolong its service life. At present, the vulcanizing machine produced by our company has a service life of 8 years as long as it is used and maintained properly. For more de...Read more -

The effect of vulcanization on the structure and properties of rubber

The effect of vulcanization on structure and properties: In the production process of rubber products, vulcanization is the last processing step. In this process, the rubber undergoes a series of complex chemical reactions, changing from a linear structure to a body-shaped structure, losing...Read more -

How to maintain the flat vulcanizer

Preparations 1. Check the amount of hydraulic oil before use. The height of hydraulic oil is 2/3 of the height of the lower machine base. When the amount of oil is insufficient, it should be added in time. The oil must be finely filtered before injection. Add pure 20# hydraulic oil into the oil f...Read more -

Features and components of rubber preforming machine

The rubber preforming machine is a high-precision and high-efficiency rubber blank making equipment. It can produce various medium and high hardness rubber blanks in various shapes, and the rubber blank has high precision and no bubbles. It is suitable for the production of rubber miscellaneous p...Read more