The production process of rubber rollers generally follows several steps, including preparation of rubber material, molding of rubber rollers, vulcanization of rubber rollers, and surface treatment. So far, most enterprises still rely on manual intermittent unit based production. In recent years, with the continuous development of injection, extrusion, and winding technologies, rubber roller molding and vulcanization equipment has gradually put rubber roller production on the fast lane of mechanization and automation. Thus, continuous production from rubber material to molding and vulcanization processes has been achieved, greatly increasing production efficiency and greatly improving the working environment and labor intensity. Due to the absence of any impurities, sand holes, and bubbles on the rubber surface of the rubber roller, there should be no scars, defects, grooves, cracks, local sponges, or differences in hardness. Therefore, only by keeping the rubber rollers absolutely clean and finely crafted throughout the entire production process, achieving unified operation and standardized technology, can the quality stability of bulk products be guaranteed. At present, the combination, bonding, injection molding, vulcanization and grinding of rubber and metal cores have become high-tech processes.

Preparation of rubber material for rubber roller production process

For rubber rollers, the mixing of rubber material is the most critical step. There are more than 10 types of rubber materials used for rubber rollers, ranging from natural rubber, synthetic rubber to special materials, with a rubber content of 25% to 85% and a hardness of soil (0-90) degrees, spanning a wide range. The conventional method is to use an open rubber mixing machine to mix and process various forms of master rubber compounds. The so-called rubber mixing machine is a type of rubber mixing machinery with exposed rollers used in rubber factories to prepare mixed rubber or to perform hot refining, roller measurements,plastic refining, and molding on rubber materials. However, these are a type of mixing plastic equipment. In recent years, enterprises have increasingly switched to using meshing internal mixers to produce rubber materials through segmented mixing.

After achieving uniform mixing, the rubber material needs to be filtered using a rubber filter machine to eliminate impurities inside the rubber material. Then use a calender, extruder, and laminating machine to make a film or strip without bubbles or impurities, which is used for forming rubber rollers. Before forming, strict visual inspection should be carried out on these films and rubber strips, and the surface should be kept fresh to prevent adhesion and compression deformation. The surface rubber of film and rubber strips should not contain impurities and bubbles, otherwise sand holes may appear when grinding the surface after vulcanization.

Rubber roller forming in the manufacturing process of rubber rollers

The molding of rubber rollers mainly involves sticking and wrapping rubber on a metal core. Common methods include wrapping, extrusion, molding, injection molding, and injection molding. At present, most domestic enterprises mainly rely on mechanical or manual bonding molding, while most foreign countries have achieved mechanical automation. Large and medium-sized manufacturing enterprises basically adopt the method of contour extrusion, using extruded film to continuously stick and form or extruded rubber strips to continuously wrap and form production. At the same time, during the molding process, the specifications, dimensions, and appearance shape are automatically controlled by a microcomputer, roller china,and some can also be molded using the right angle and irregular extrusion methods of an extruder.

The use of imitation extrusion and microcomputer automatic control molding methods can eliminate possible bubbles and minimize labor intensity to the greatest extent possible. In order to prevent deformation during the vulcanization of the rubber roller and prevent the generation of bubbles and sponges, hina rubber corona pressure roller custom,a flexible pressure method should also be used externally for the molding process of the wrapping method. Usually, several layers of cotton or nylon cloth are wrapped around the surface of the rubber roller, rubber roller hardness unit,and then fixed and pressed with steel wire or fiber rope.

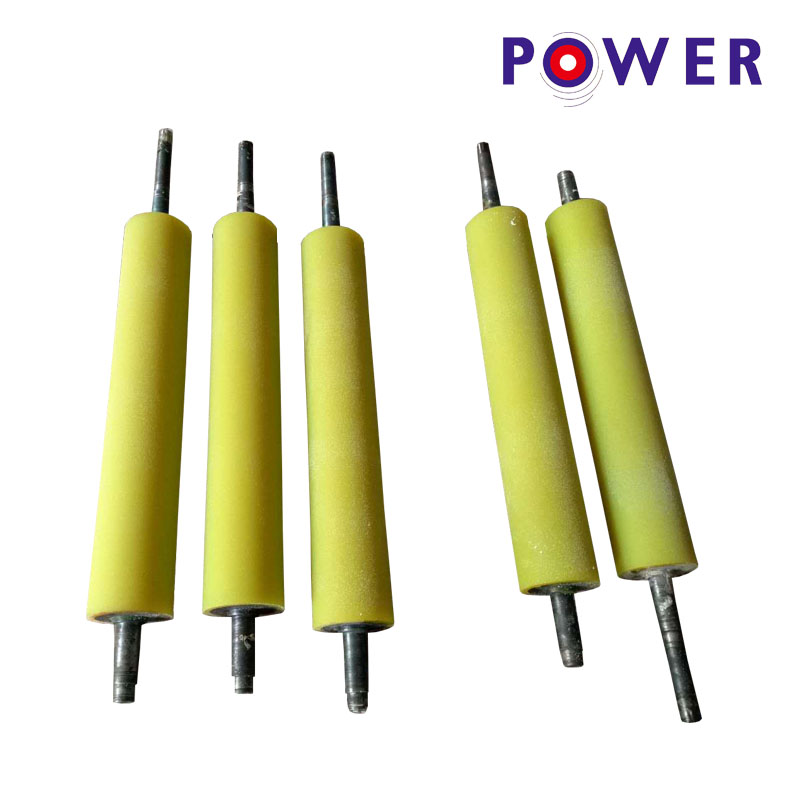

For small and micro rubber rollers, various production processes such as manual patching, extrusion nesting, injection molding, injection molding, and pouring can be used. In order to improve production efficiency, molding methods are now mostly used, and the accuracy is much higher than non molding methods. The injection and pressing of solid rubber, as well as the pouring of liquid rubber, have become the most important production methods.

Post time: Jul-25-2024