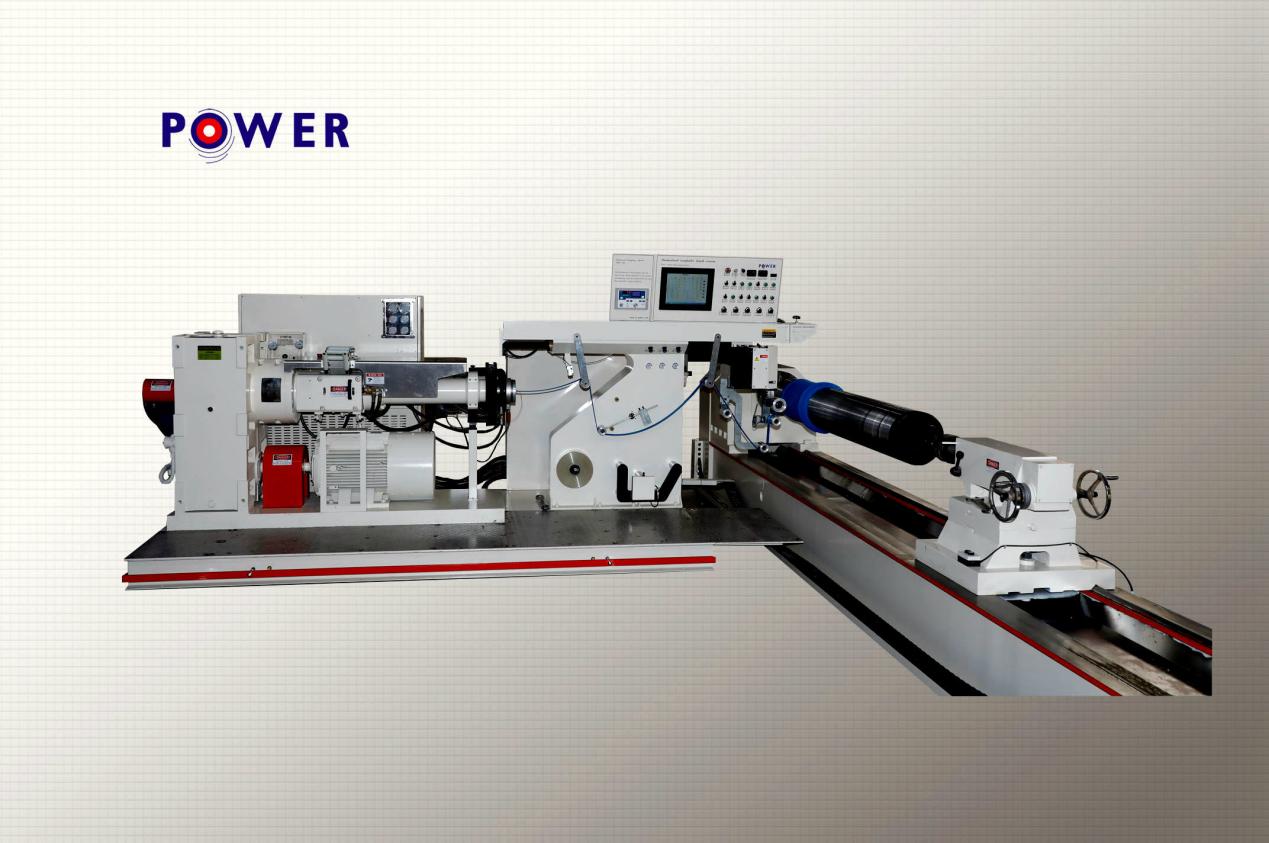

Rubber roller covering machines play a crucial role in various industries where rollers are utilized for diverse applications. These machines are designed to cover rollers with different types of rubber materials, enhancing their performance, durability, and efficiency. As technology continues to evolve, the future prospects of rubber roller covering machines look promising, with advancements in automation, materials, and customization capabilities. In this article, we will explore the emerging trends, benefits, challenges, and growth opportunities in the field of rubber roller covering machines.

Emerging Trends in Rubber Roller Covering Machines:

Automation and Robotics: The integration of automation and robotics in rubber roller covering machines is a growing trend, enabling faster production cycles, precise covering processes, and reduced manual intervention.

Smart Manufacturing: Industry 4.0 concepts are being incorporated into rubber roller covering machines, allowing for real-time monitoring, predictive maintenance, and data-driven optimization of production processes.

IoT Connectivity: Internet of Things (IoT) connectivity is being leveraged in rubber roller covering machines for remote monitoring, diagnostics, and performance tracking, enhancing operational efficiency and uptime.

Customization and Flexibility: Manufacturers are focusing on enhancing the customization capabilities of rubber roller covering machines to meet the specific requirements of diverse industries and applications.

Sustainable Practices: Incorporating eco-friendly materials, energy-efficient components, and waste reduction strategies in rubber roller covering machines is an emerging trend driven by the increasing focus on sustainability.

Benefits of Rubber Roller Covering Machines:

Improved Performance: Rubber roller covering machines enhance the grip, traction, and wear resistance of rollers, leading to improved overall performance and efficiency in various industrial processes.

Cost Savings: By extending the lifespan of rollers and reducing maintenance costs, rubber roller covering machines offer long-term cost savings for companies.

Enhanced Quality Control: These machines ensure consistent and precise covering of rollers, resulting in higher quality output and customer satisfaction.

Versatility: Rubber roller covering machines can work with a wide range of rubber materials, allowing for customization and adaptation to different applications and industries.

Increased Productivity: The efficiency and automation capabilities of rubber roller covering machines contribute to increased productivity, shorter lead times, and optimized production workflows.

Challenges and Growth Opportunities:

Technological Adoption: Encouraging the adoption of advanced rubber roller covering machines among smaller manufacturers and ensuring proper training and support for operators are key challenges to address.

Market Competition: As the demand for improved roller quality and performance grows, companies must differentiate themselves through innovation, service offerings, and value-added solutions.

Material Innovation: Developing new rubber compounds, additives, and coatings for roller covering materials to enhance durability, friction properties, and sustainability presents opportunities for growth and differentiation.

Global Expansion: Expanding into new markets and industries that require specialized roller covering solutions opens up growth opportunities for manufacturers of rubber roller covering machines.

Service and Maintenance: Providing comprehensive service contracts, maintenance programs, and technical support for rubber roller covering machines is crucial for ensuring long-term customer satisfaction and loyalty.

In conclusion, the future prospects of rubber roller covering machines are bright, fueled by technological advancements, industry trends, and the increasing demand for high-performance rollers in various sectors. By embracing innovation, sustainability, customization, and automation, manufacturers of rubber roller covering machines can capitalize on the growth opportunities in the market, address challenges effectively, and cater to the evolving needs of industries that rely on high-quality rollers for their operations.

Post time: Jul-10-2024