The important role of rubber coating machines in industrial applications

The important role of rubber coating machines in industrial applications

The importance of rubber components in the world of industrial manufacturing cannot be overstated. Rubber rollers, in particular, play a vital role in a variety of applications such as printing, dyeing, industrial conveying, and papermaking machinery. To ensure the efficiency and life of these rubber rollers, specialized equipment is required. Among them, rubber roller winding machines are important tools for rubber roller processing. This article delves into the importance of rubber coating machines, including rubber coating machines, pulley rubber grooving machines, drum rubber coating machines, and drum rubber covering machines, all of which contribute to the efficient production and maintenance of rubber rollers.

Learn about Rubber Roller Winding Machine

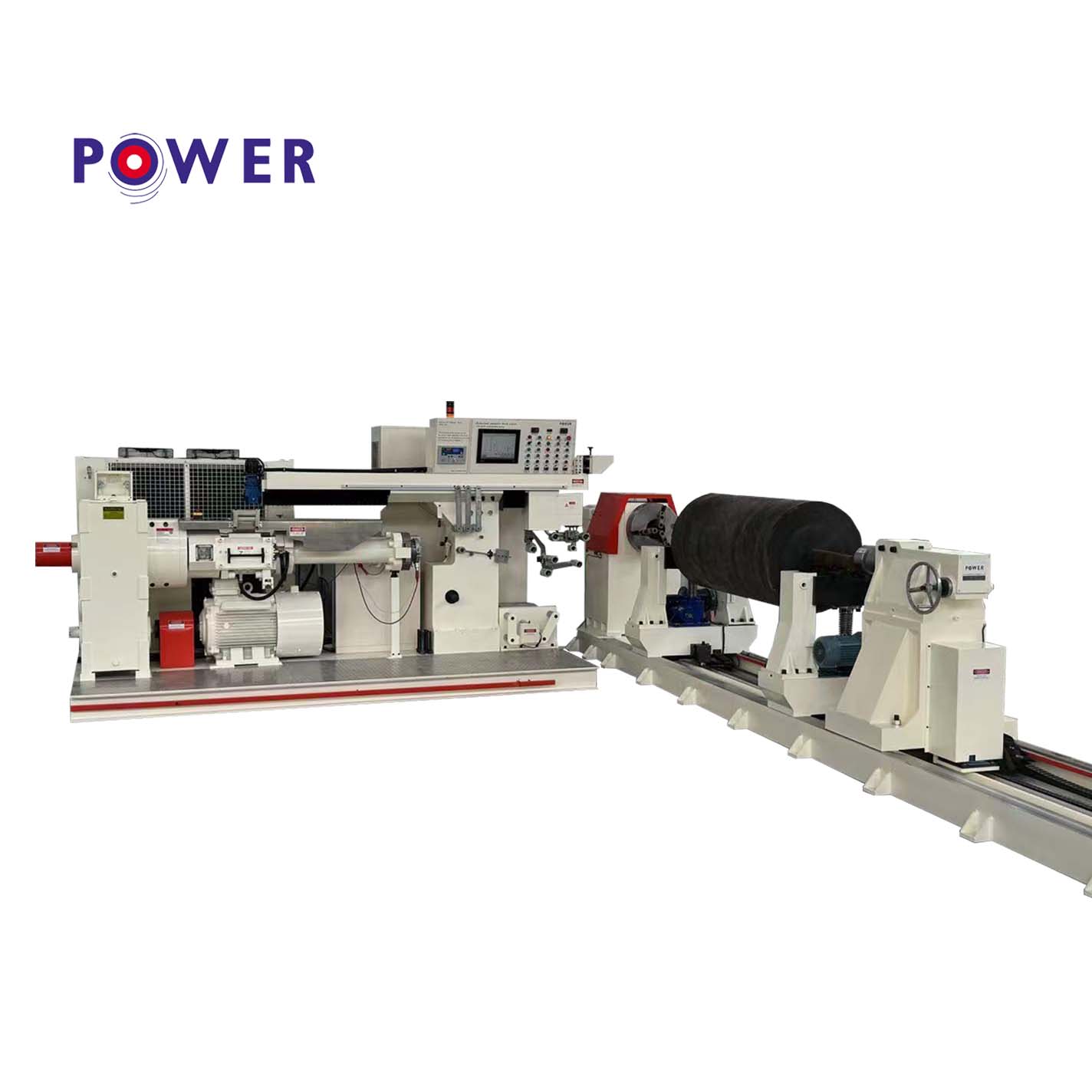

As the name implies, a rubber roll winding machine is specifically designed for processing rubber rolls. The equipment is designed to apply a rubber coating to the roll, ensuring that it meets the necessary specifications for a variety of industrial applications. The machine operates by winding the rubber material around a mandrel (which can be a metal or plastic roll) to create a durable and practical rubber surface.

Rubber rollers are used in a wide range of applications and are an essential component in many industries. For example, in the printing industry, rubber rollers are used to transfer ink to paper, ensuring that the ink is evenly distributed and the print quality is high. In the dyeing process, rubber rollers help apply dye to fabrics; in industrial conveying, rubber rollers help goods move along conveyor belts. The papermaking industry also relies heavily on rubber rollers at various stages of production, from pressing to dryiThe function of rubber coating machine

Rubber coating machines are essential for applying an even layer of rubber to a variety of substrates. These machines ensure that the rubber coating is of consistent thickness and adheres properly to the surface. This is especially important in applications where precision is critical, such as in the manufacture of printing and paper cylinders.

The rubber coating machine works by feeding the substrate into a series of rollers that are coated with the rubber material. The process can be adjusted to accommodate different types of rubber and various thicknesses, making it a versatile tool in rubber processing. The quality of the rubber coating directly affects the performance of the final product, carbon fiber roller rubber roller manufacturer,so the rubber coating machine is an integral part of the manufacturing process.

Pulley rubber slotting machine

Another key piece of equipment in the rubber processing industry is the pulley rubber grooving machine. This machine is used to create grooves on rubber coated pulleys, which is essential to ensure proper grip and function in a variety of applications. The grooves provide better traction and help prevent slipping, which is critical for machinery that relies on pulleys for movement.

Rubber grooving machines operate by cutting precise grooves into the rubber surface of a pulley, china supply long rubber strip feeder manufacturers,ensuring accurate and consistent dimensions. Whether in conveyor systems, automotive engines, or other machinery, this precision is critical to the performance of the pulley in its intended application.

Roller Rubber Coating and Covering Machine

Drum rubber coating machines and drum rubber covering machines are specialized tools designed to apply rubber to drums. These machines are designed to handle various sizes and types of drums, allowing them to meet different industrial needs. The coating process involves applying a layer of rubber to the surface of the drum, thereby improving its durability and performance.

Drum rubber coating machines typically use advanced technology to ensure that the rubber is evenly applied, which is essential to maintaining the integrity of the drum during operation. Similarly, drum rubber covering machines are designed to cover the entire surface of the drum, providing a protective layer that can withstand wear and tear.

in conclusion

In summary, rubber roller winding machines and their supporting equipment, including glue coating machines, pulley glue groove machines, drum glue coating machines, drum glue wrapping machines, etc., play a vital role in rubber roller processing and maintenance. These machines ensure that rubber rollers are produced to the highest standards to meet the needs of various industries such as printing, dyeing, industrial conveying and papermaking.

As the industry continues to evolve and the demand for higher quality, more efficient products increases, the importance of specialized rubber processing equipment will only grow. Investing in advanced rubber coating machines will not only improve the quality of the final product, but also increase the overall efficiency and productivity of the manufacturing process. For businesses looking to maintain a competitive edge, understanding and utilizing these essential tools is key to success in the rubber processing industry.

Post time: Jan-17-2025