PriceList for Rubber Sleeve Processing Line - Rubber Roller Covering Machine – Power

PriceList for Rubber Sleeve Processing Line - Rubber Roller Covering Machine – Power Detail:

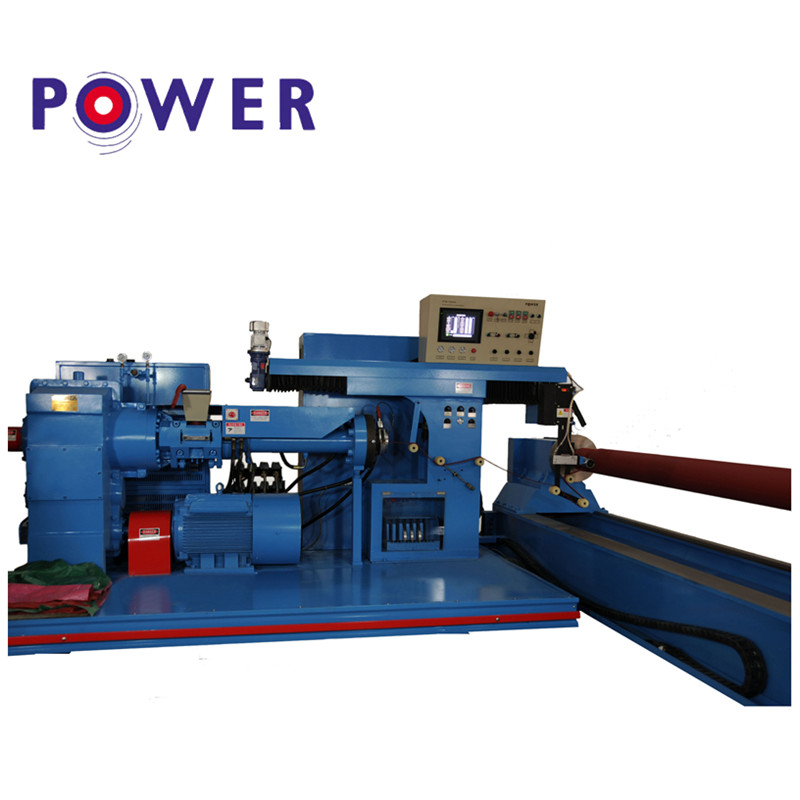

Product Description

1. Applicable to the types of rubber roller processing:

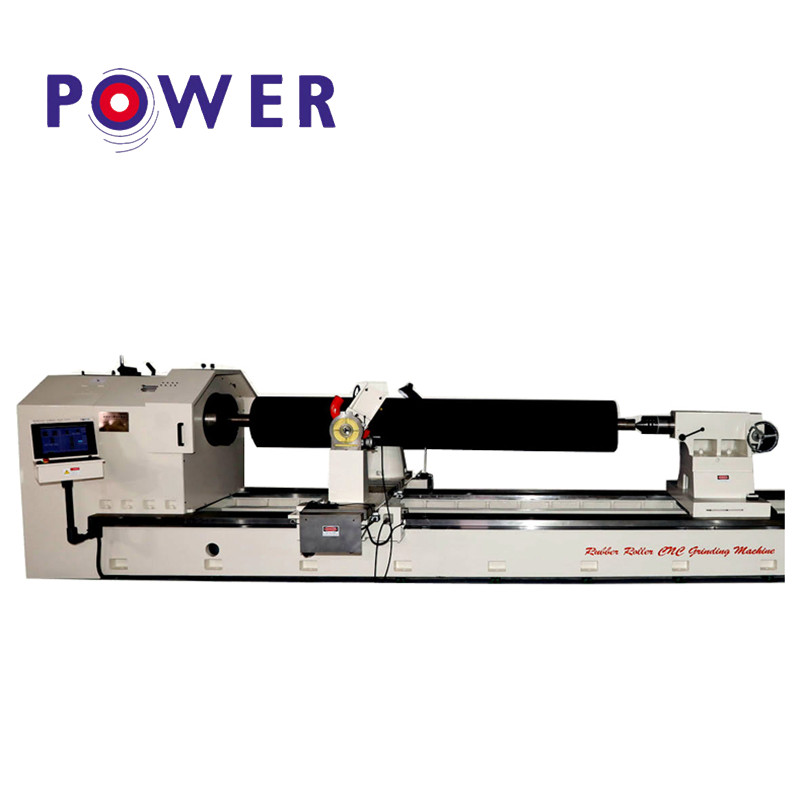

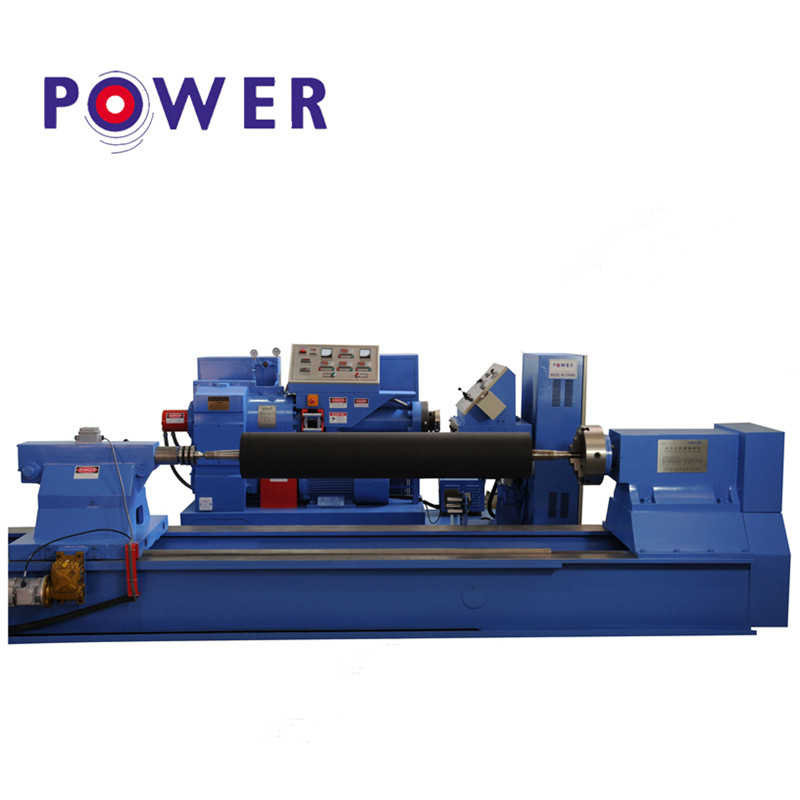

(1)The PTM-4030 & PTM-8060 models are suitable for rubber covering process on printing rollers, general industrial rollers and small industrial rubber rollers.

(2)The PTM-1060 model is suitable for processing general industrial rollers and small paper rubber rollers.

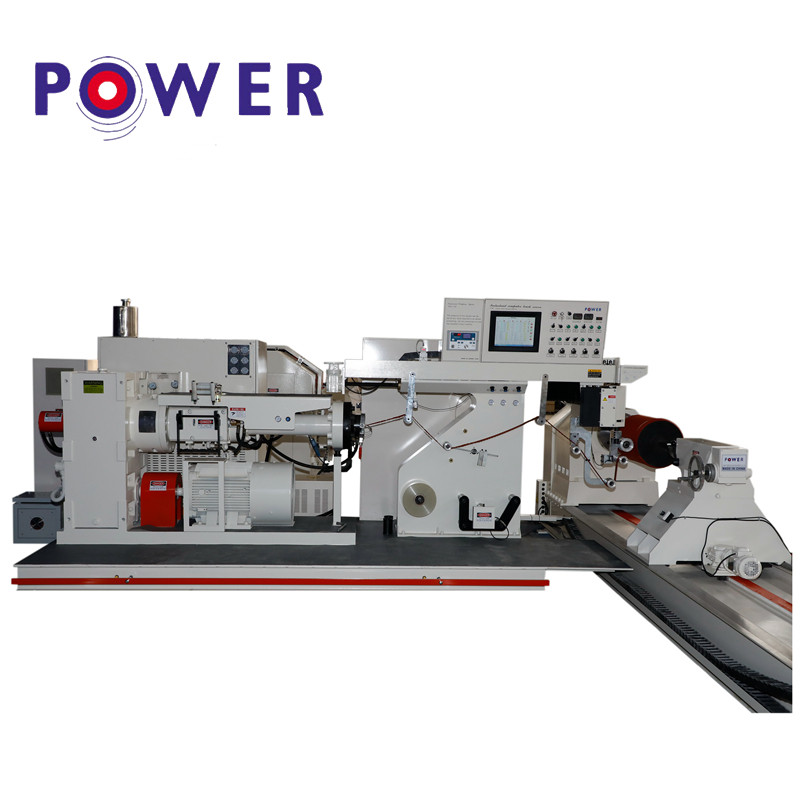

(3)The PTM-1580 & PTM-2010 models are suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

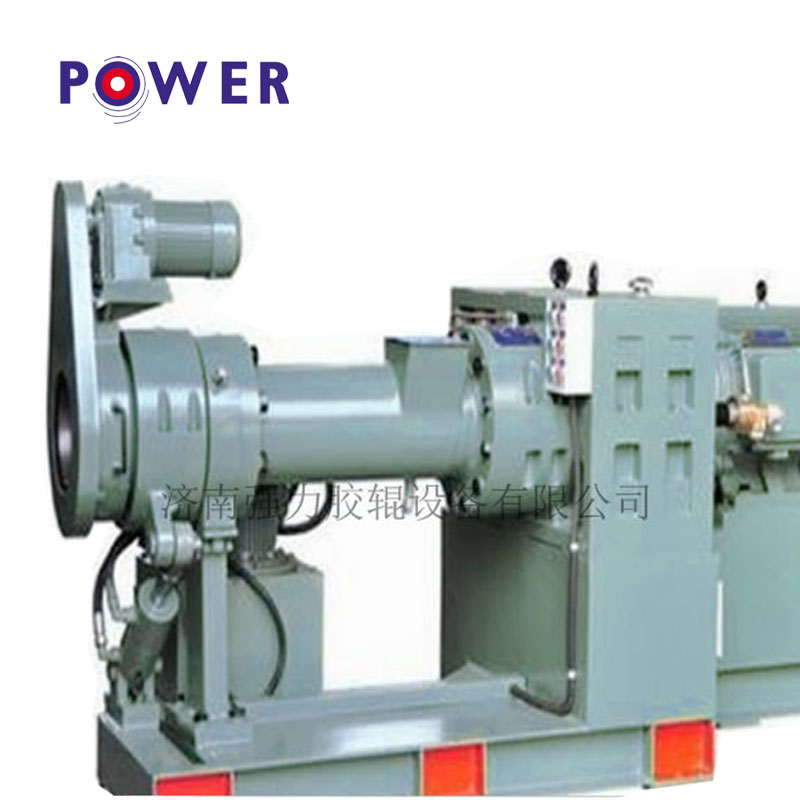

2. Equipped with E250CS, E300CS, E350CS or E400CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support on-line or on-site.

5. Optional nylon type wrapping function, and other special design can be provided upon customer requirement.

| Model Number | PTM-4030 | PTM-8060 | PTM-1060 | PTM-1580 | PTM-2010 |

| Max Diameter | 16″/400mm | 32″/800mm | 40″/1000mm | 59″/1500mm | 79″/2000mm |

| Max Length | 118″/3000mm | 236″/6000mm | 236″/6000mm | 315″/8000mm | 394″/10000mm |

| Work Piece Weight | 500kg | 1500kg | 3000kg | 8000kg | 10000kg |

| Hardness Range | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A |

| Voltage (V) | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 |

| Power (KW) | 25 | 45 | 55 | 75 | 95 |

| Extruder | E250CS | E300CS/E350CS | E350CS | E350CS/E400CS | E350CS/E400CS |

| Screw diameter | 2.5″ | 3″/3.5” | 3″/3.5” | 3.5″/4.0” | 3.5″/4.0” |

| Feeding Method | Cold feeding | Cold feeding | Cold feeding | Cold feeding | Cold feeding |

| Extruder Output | 4.2kg/min | 5.6kg/min | 6.6kg/min | 6.6kg/min | 6.6kg/min |

| Brand Name | POWER | POWER | POWER | POWER | POWER |

| Certification | CE,ISO | CE,ISO | CE,ISO | CE,ISO | CE,ISO |

| Warranty | 1 year | 1 year | 1 year | 1 year | 1 year |

| Color | Customized | Customized | Customized | Customized | Customized |

| Condition | New | New | New | New | New |

| Place of Origin | Jinan, China | Jinan, China | Jinan, China | Jinan, China | Jinan, China |

| Need of operator | 1-2 person | 1-2 person | 1-2 person | 1-2 person | 1-2 person |

Application

The automatic rubber roller covering machine is designed and produced for improving the rubber covering process. Appropriate models can be selected for different industries. Advanced and mature technology will bring higher efficiency to the roller production.

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of PriceList for Rubber Sleeve Processing Line - Rubber Roller Covering Machine – Power , The product will supply to all over the world, such as: Turkmenistan, Pakistan, United Arab Emirates, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.