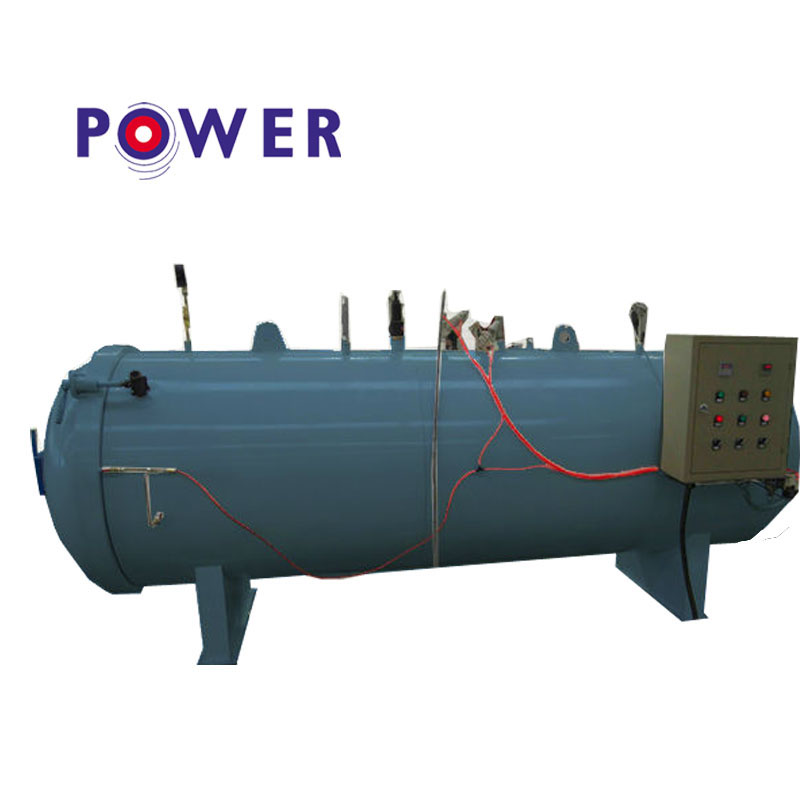

Professional China Injection Vulcanizing Machine - Autoclave- Steam Heating Type – Power

Professional China Injection Vulcanizing Machine - Autoclave- Steam Heating Type – Power Detail:

Product Description

1. Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.

2. Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve. The air source is depressurized by a set of filter and pressure reducing purification device. Copper pipe is used for pipeline connection.

3. Steam pipeline system: the steam pipeline system shall refer to the drawings design and configuration provided by the manufacturer. The pipeline layout is reasonable, beautiful and convenient for operation and maintenance. Reliable pipeline connection.

4. Vacuum system of vulcanizing tank: used to control the vacuum absorption.

5. Control system: semi-automatic or full-automatic control system, including temperature control, pressure control, etc.

| Model |

φ1500mm×5000mm |

φ1500mm×8000mm |

| Diameter |

φ1500mm |

φ1500mm |

| Straight length |

5000mm |

8000mm |

| Heating mode |

direct steam heating |

direct steam heating |

| Design pressure |

0.8Mpa |

1.58Mpa |

| Design temperature |

175 °C |

203 °C |

| Steel plate thickness |

8mm |

14mm |

| Temperature measurement and control point |

2 points |

2 points |

| Ambient temperature |

Min.-10 ℃ - Max. +40℃ |

Min.-10 ℃ - Max. +40℃ |

| Power |

380, three-phase five-wire system |

380V, three-phase four-wire system |

| Frequency |

50Hz |

50Hz |

Application

Vulcanization of rubber products.

Services

1. Installation service.

2. Maintenance service.

3. Technical support online service provided.

4. Technical files service provided.

5. On-site training service provided.

6. Spare parts replacement and repair service provided.

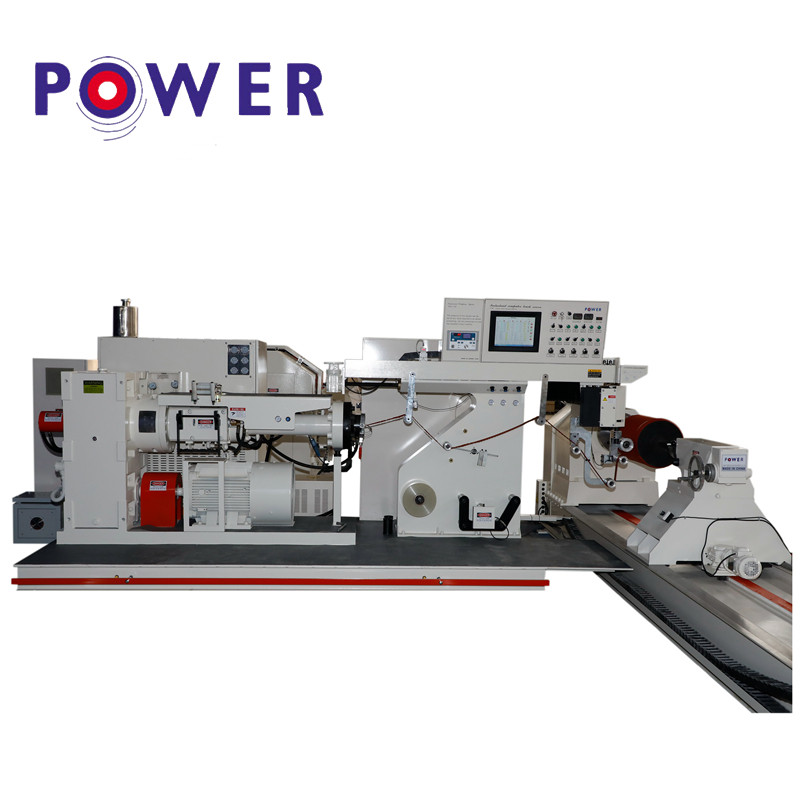

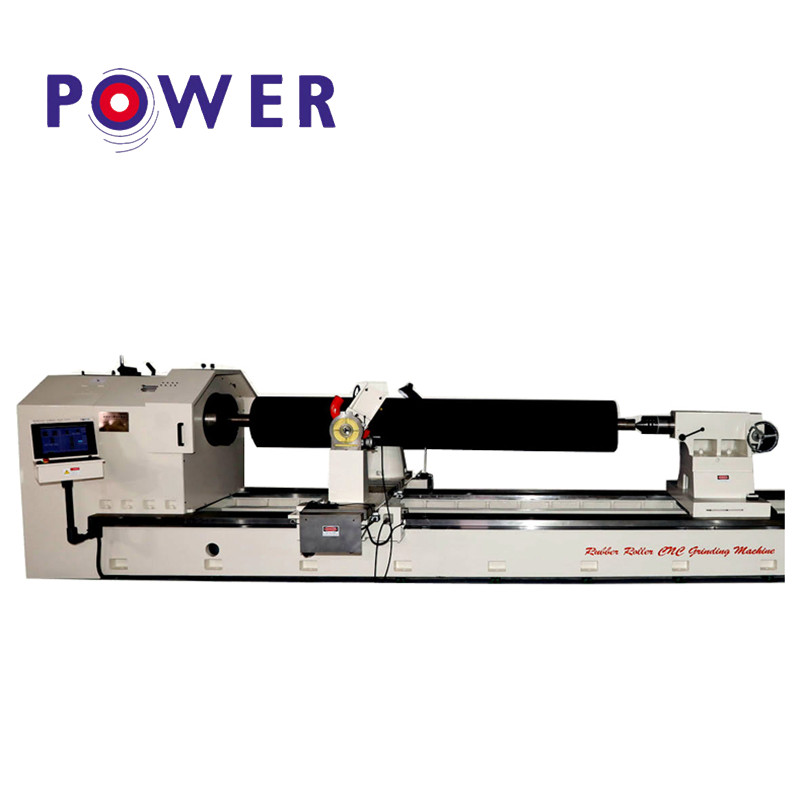

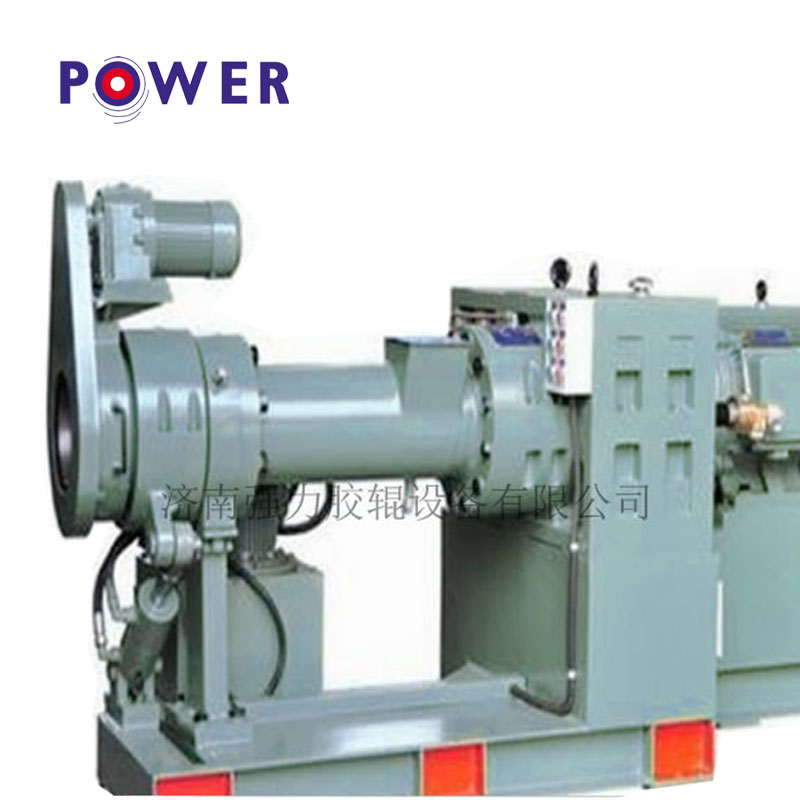

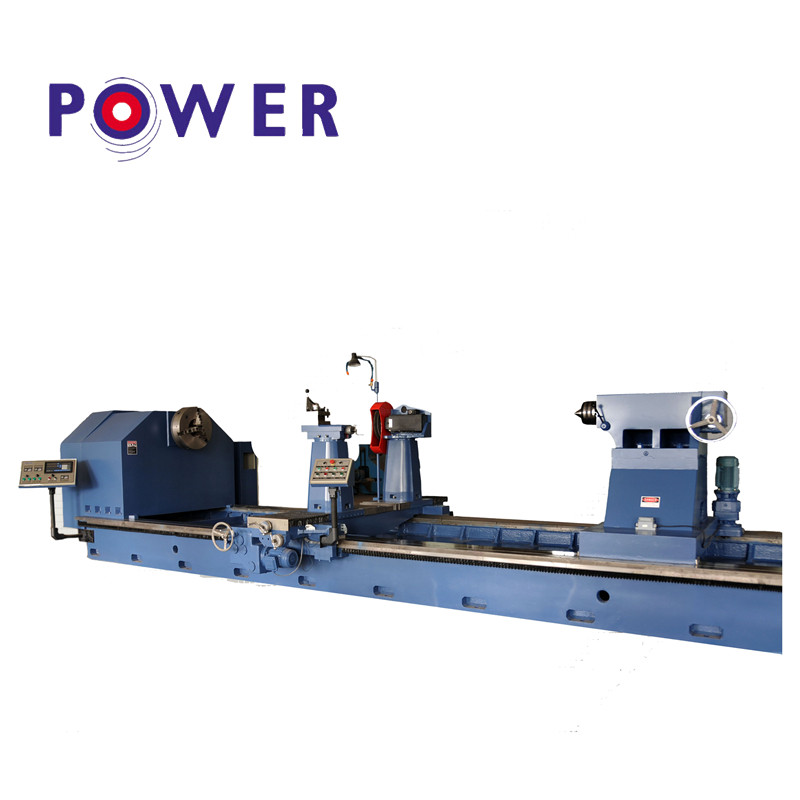

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Professional China Injection Vulcanizing Machine - Autoclave- Steam Heating Type – Power , The product will supply to all over the world, such as: Bhutan, Romania, Costa rica, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!