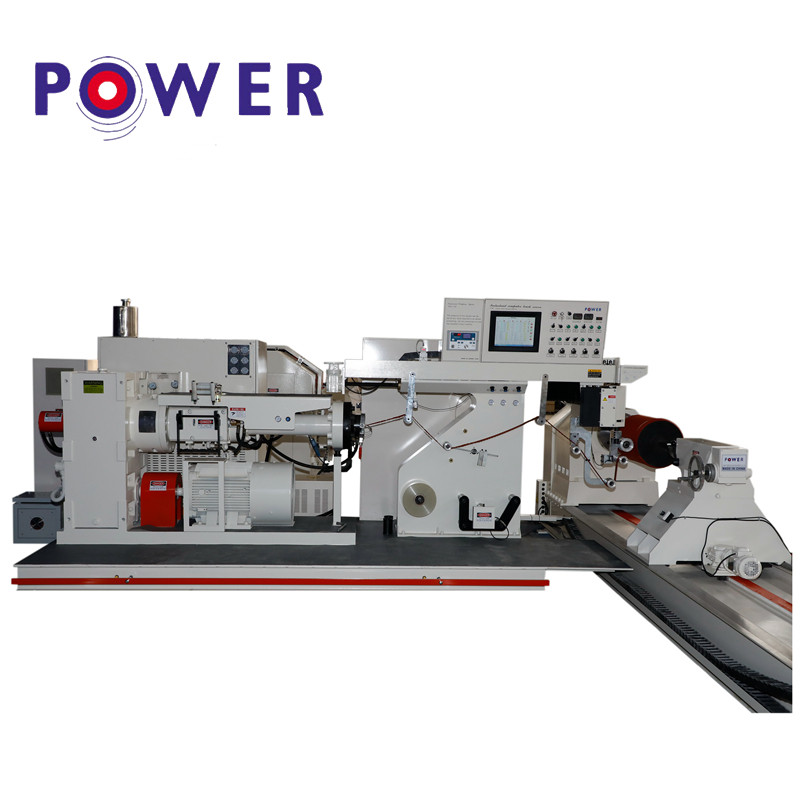

Professional China Rubber Compound - Rubber Roller Multi-purpose Stripping Machine – Power

Professional China Rubber Compound - Rubber Roller Multi-purpose Stripping Machine – Power Detail:

Product Description

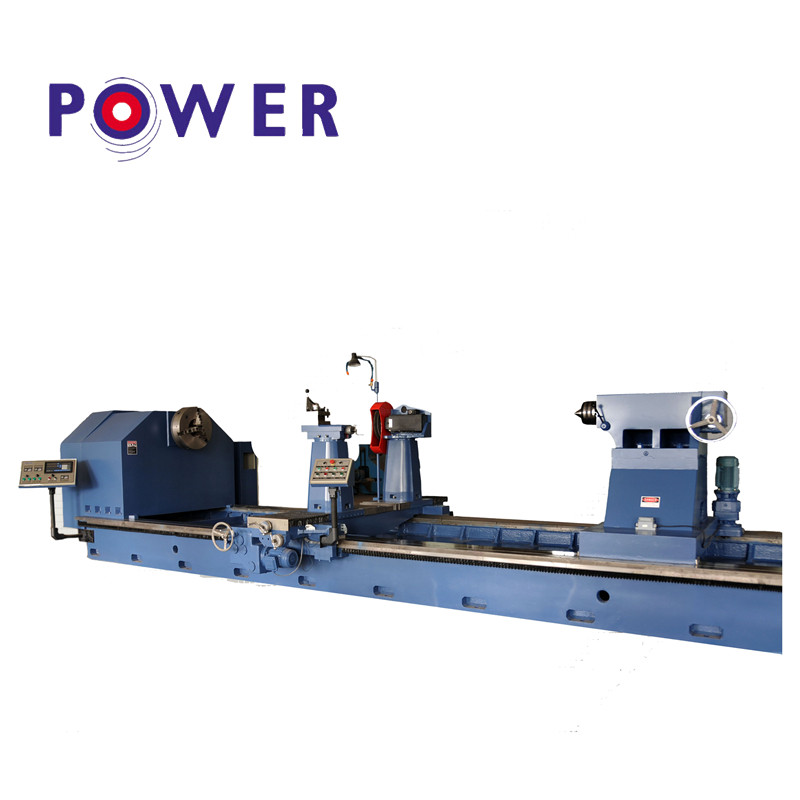

1. The PCM-4030 & PCM-6040 models are suitable for renewing printing rollers, general industrial rollers and small industrial rubber rollers. The PCM-8040, PCM-1250 & PCM-1660 models are suitable for renewing industrial rubber rollers.

2. Removing old rubber by special ring cutter.

3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.

4. Perfectly keeping the original dynamic balance of the roller core.

5. Giving more reliable guarantee for the bonding of the rubber and steel cores.

6. Saving costs and labors with this improved production system.

| Model Number | PCM-4030 | PCM-6040 | PCM-8040 | PCM-1250 | PCM-1660 |

| Max Diameter | 15.7″/400mm | 24″/600mm | 31.5″/800mm | 47.2″/1200mm | 63″/1600mm |

| Max Length | 118″/3000mm | 157.5″/4000mm | 157.5″/4000mm | 196.9″/5000mm | 236.2″/6000mm |

| Work Piece Weight | 500kg | 800kg | 1000kg | 2000kg | 3000kg |

| Hardness Range | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A |

| Voltage (V) | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 |

| Power (KW) | 8.5 | 8.5 | 12 | 19 | 23 |

| Dimension | 5m*1.6m*1.4m | 6m*1.7m*1.5m | 6m*1.8m*1.6m | 7.8m*2.0m*1.7m | 8.6m*2.6m*1.8m |

| Brand Name | POWER | POWER | POWER | POWER | POWER |

| Certification | CE,ISO | CE,ISO | CE,ISO | CE,ISO | CE,ISO |

| Warranty | 1 year | 1 year | 1 year | 1 year | 1 year |

| Color | Customized | Customized | Customized | Customized | Customized |

| Condition | New | New | New | New | New |

| Place of Origin | Jinan, China | Jinan, China | Jinan, China | Jinan, China | Jinan, China |

| Need of operator | 1 person | 1 person | 1 person | 1 person | 1 person |

Application

PCM Multi-purpose Stripping Machine is specially researched, developed and designed for treating old rubber rollers. PCM Multi-purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process. After the belt grinding process, the surface is not required to be cleaned by any solvent, the balance of the roller core is prevented from being damaged. Therefore, production efficiency will be improved, cost and labor will be saved. Most importantly, the bonding of the rubber and the roller core will be secured by this procedure.

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Professional China Rubber Compound - Rubber Roller Multi-purpose Stripping Machine – Power , The product will supply to all over the world, such as: Lesotho, Algeria, Iran, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.