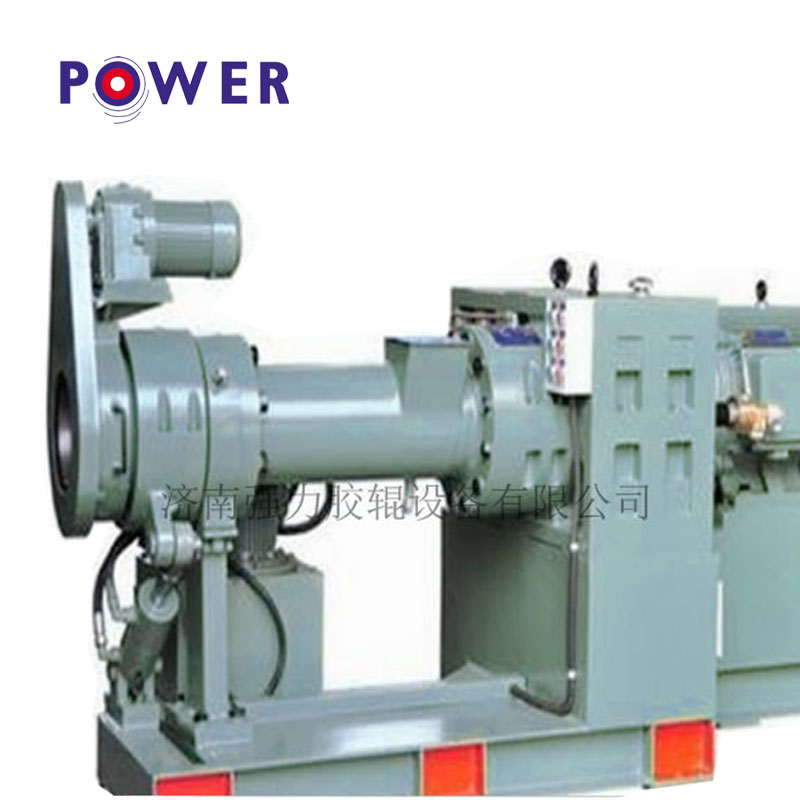

Rubber Filter/ Rubber Strainer

Selection of Rubber Filter

1. Pressure rubber filter – Suitable for soft rubber compound that does not need remix.

Feature: easy to clean, can extrude through 200 mush filter, bigger output.

2. Screw rubber filter – Suitable for all kinds of rubber compound for the roller industry.

Feature: large range of rubber compound can be filtered.

1)Single screw type:

Standard single screw type – Suitable for compound between 25-95Sh-A, but not for high viscosity rubber, such as silicon etc.

Enforce feeding single screw type – Suitable for all kinds of rubber compound between 25-95Sh-A, even for high viscosity rubber, such as silicon, EPDM, Hypalon, etc.

2)Dual-screw type:

Enforce feeding dual-screw type – Suitable for all kinds of rubber compound between 25-95Sh-A, even for high viscosity rubber, such as silicon, EPDM, Hypalon, etc.

Enforce feeding dual-screw with TCU type – Suitable for compound between 25-100Sh-A, especially suitable for temperature sensitive compound.

|

Dual-Screw Rubber Filter Parameter |

|||||

| Type/Series |

φ115 type |

φ150 type |

φ200 type |

φ250 type |

φ300 type |

| Screw diameter (mm) |

115 |

150 |

200 |

250 |

300 |

| Reducer specification |

225 Gear box |

250 Gear box |

280 Gear box |

330 Gear box |

375 Gear box |

| Length-diameter ratio of the screw (L/D) |

6:01 |

1.8:1 |

2.7:1 |

3.6:1 |

3.6:1 |

| Screw highest speeds (RPM) |

45 |

45 |

40 |

40 |

35 |

| Motor power (KW) |

45 |

45~55 |

70~90 |

90~110 |

130~160 |

| Power voltage (V) |

380 |

380 |

380 |

380 |

380 |

| Maximum output (KG/HOUR) |

240 |

300 |

355 |

445 |

465 |

| Refrigerating unit compressor power |

5P |

5P |

5P |

7.5P |

7.5P |

Selection of Length-Diameter Ratio:

1. If there is sand in the rubber, the length-diameter ratio of screw should be selected for a larger one.

2. The advantage of the large length-diameter ratio of the screw is that the working part of the screw is long, the plastic material is plasticized, the mixing is uniform, the rubber is subjected to high pressure and the product quality is good. However, if the screw is long, it will easily cause the rubber to burn, and the screw processing is difficult, and the extrusion power is increased.

3. The screw used for the hot feed extrusion rubber machine generally takes a length-diameter ratio of 4 to 6 times, and the screw for the cold feed extrusion rubber machine generally takes an length-diameter ratio of 8 to 12 times.

Advantages of increasing length-diameter ratio

1)The screw is fully pressurized, and the physical and mechanical properties of the products can be improved.

2)Good plasticization of materials and good appearance quality of products.

3)Increase the extrusion volume by 20-40%. At the same time, the characteristic curve of screw with large length-diameter ratio has a low slope, relatively flat, and stable extrusion volume.

4)Good for powder molding, such as PVC powder extrusion tube.

Disadvantages of increasing length-diameter ratio:

Increasing length-diameter ratio makes the manufacture of screw and the assembly of screw and barrel difficult. Therefore, the length-diameter ratio cannot be increased without limitation.

Services

1. Installation service.

2. Maintenance service.

3. Technical support online service provided.

4. Technical files service provided.

5. On-site training service provided.

6. Spare parts replacement and repair service provided.