Rubber Roller CNC Grinding Machine

Product Description

1. Own developed user-friendly CNC operating system.

2. The latest system can easily operate 35 processing schemes on the rubber roller surface, which includes cuttings, grindings, groovings and combinations.

3. Remote on-line trouble shooting function can be selected.

4. Motorized angle turning grooving head can be selected.

5. Having all the functions of our PSM series general grinding machine as following.

1)Standard equipment of PSM series includes:

a.a full flood re-circulating coolant system

b.motorized tailstock

c.variable speed travels and spindle drives

d.front and rear independently operated carriage tables

e.a direct drive grinding head mounted on the rear

2)Specially designed to replace the traditional roller grinding process method.

3)Two medium carriage tables assembled to ensure accurate performance and operating stability.

4)The max. linear speed of grinding head is over 90m/s. Production efficiency is highly increased and the geometric size is guaranteed.

5)Advanced measuring device assembled timely checks the processing data and provides effective help to control the grinding size can be upgrade upon request.

6)Capable of realizing expansion of processing of special-shaped rubber rollers.

| Name | Model | Metal/Rubber | Dia. | Leng | Weight | ||

| Rubber R Grinding Machine | PSM-4020/D | No/Yes | 400 | 2000 | 500 | ||

| Rubber R Grinding Machine | PSM-6030/D | No/Yes | 600 | 4000 | 2000 | ||

| Rubber R Grinding Machine | PSM-8040/D | No/Yes | 800 | 4000 | 5000 | ||

| Rubber R Grinding Machine | PSM-1250/D | No/Yes | 1000 | 6000 | 6000 | ||

| Rubber R Grinding Machine | PSM-1460/D | No/Yes | 1200 | 8000 | 8000 | ||

| Rubber R Grinding Machine | PSM-Customize | No/Yes | optional | optional | optional | ||

| Remarks | D: Industrial computer T: Touch Screen | ||||||

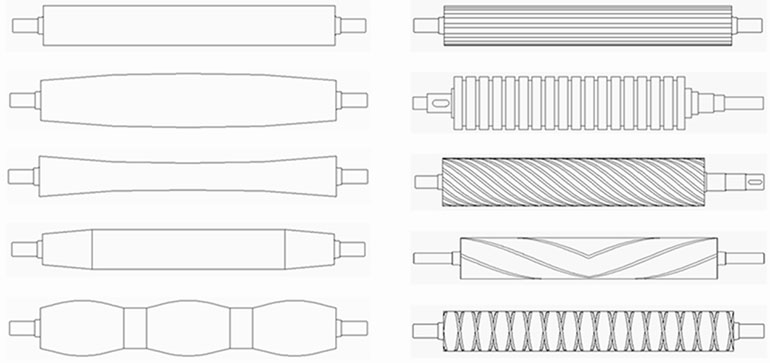

Roller Profile

The system has an all-round comprehensive processing function, with a total of 35 processing schemes:

It has 5 kinds of shape cutting functions, 5 kinds of grinding functions of roll shape (Flat Grinding, Middle Convexity Grinding, Middle Concave Crown Grinding, Hammer Head Grinding, Waveform Grinding), and 25 kinds of functions of processing 5 grooves (Vertical groove, Spiral groove, Rhombus groove, Man-shape groove and Level groove) on 5 kinds of roller shape respectively.

Application

Base on the basic PSM series general grinding machine, PSM-CNC series is developed by changed the driven type and control system. CNC system is specialized digital-controlled software for roll processing. Jinan Power Rubber Roller Equipment Company and the institutions of scientific research develop the software. Its professional performance characteristics are the best among the machining industry. Due to the all-round of the system function, it can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations.

Services

1. On-site installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.